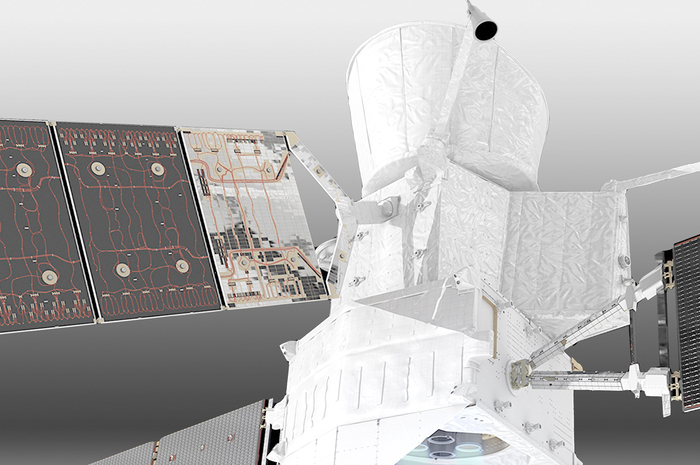

CNC manufacturing for Aviation and Aerospace

Aerospace components for aeroplanes

In CNC manufacturing for the aviation industry, we are your worry-free full-service provider in certified EN 9100:2018 quality.

Learn more

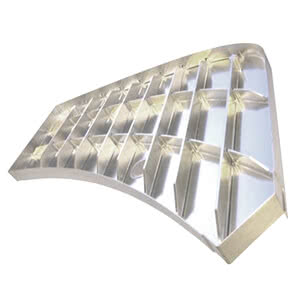

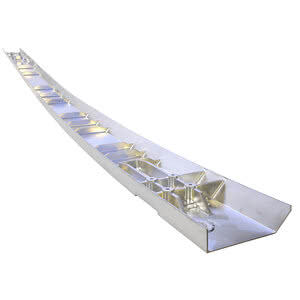

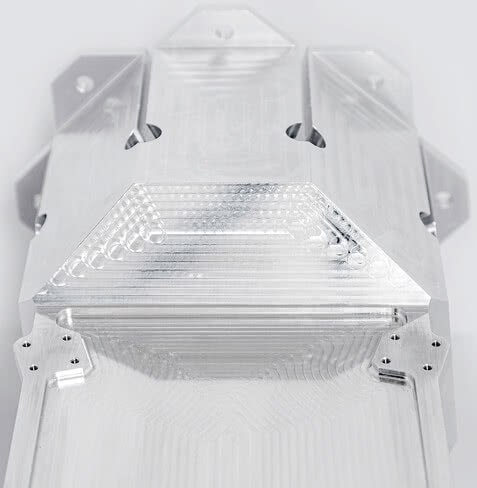

Aerospace lightweight components

As an experienced aerospace project partner, we supply the aerospace industry with high-precision and robust aluminium and titanium lightweight components.

Learn more

Helicopter components

With our special experience in lightweight construction, we mill special parts and tools/moulds from aluminium, steel, titanium, Invar, GRP, CFRP for helicopters and MRO.

Learn more

Drone components

CNC-milled parts made of carbon fibre composites, aluminium alloys and titanium alloys for unmanned airborne reconnaissance systems.

learn more

MRO Aviation Spareparts Service

Laro NC-Technik manufactures high-precision spare parts for continuous aircraft maintenance, repair and overhaul (MRO) in accordance with the EN 9100:2018 standard.

Learn more

Mechanical Ground Support Equipment

We also manufacture "non-flying" CNC components for Mechanical Ground Support Equipment (MGSE) with the highest precision and the required certified quality.

Find out more

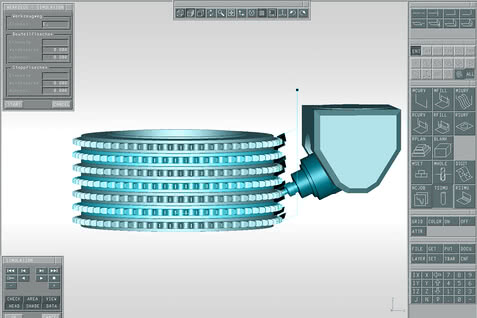

Milling large parts to the perfect finish

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

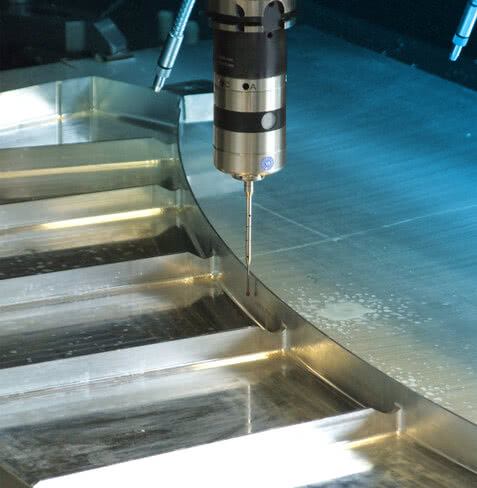

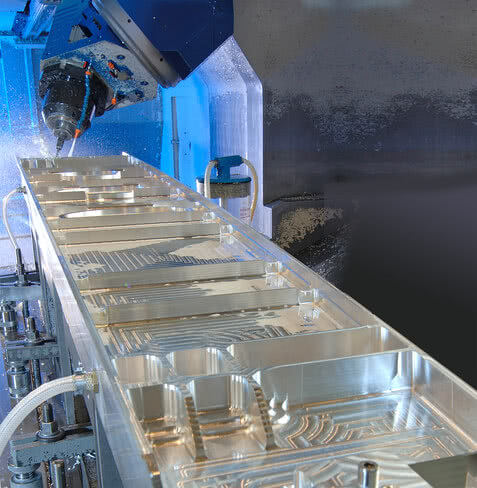

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

AVIATION AND AEROSPACE PARTSWhat makes us the ideal partner for demanding projects?

We apply the high standards required in the aerospace industry on a daily basis. We are therefore very familiar with the typical requirements in this sector. We offer you high-quality and dimensionally accurate parts that fulfil even the highest demands. Our employees look forward to every new challenge and your customised project!

As a generalist CNC service provider, we provide you with all services from a single source. Depending on your requirements, we also take on individual upstream or downstream work steps in addition to machining. We even consistently "think along" with the process steps outside our company. Because we want to support you in the realisation of your project as effectively as possible.

Our wide-ranging expertise and modern machinery make us the ideal partner for every situation. Convince yourself of the expertise and commitment of our employees.

Make an appointment now for a non-binding consultation!

PERFORMANCE CAPABILITY

What requirements must aerospace components fulfil?

- maximum lightness for cost-effectiveness and energy efficiency

- absolute safety and high load capacity

- Flexible production and punctual deliveries

- In-depth expertise for comprehensive advice and solution finding

- Complete documentation and reliable traceability

We find the right solution for every component. High-speed cutting (HSC milling) enables aerospace parts to be manufactured particularly quickly. From thin-walled workpieces with low weight to heavy-duty machining: we have solutions for practically every project. We manufacture highly complex components and guarantee you continuous process reliability.

CNC machinery: plenty of working space for large-volume machining

High Performance Cutting

High Speed Cutting

Working area X = 6000mm, Y = 3500mm, Z = 1500mm

Working area X = 6000mm, Y = 2850mm, Z = 2100mm

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

Bavius UBZ NT 300/200

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

Working area X = 2300mm, Y = 1600mm, Z = 900mm

QUALITY PROMISE

How do we ensure completely satisfied customers?

The following points also characterise us as an ideal CNC service provider - especially for the aerospace industry:

EN 9100:2018 certification

Our EN 9100:2018 certification confirms what our customers have long known: Absolute reliability and the highest quality are our standard. Your aerospace components are in the best hands with us.

You can find more information about our EN 9100:2018 certification here.

Feasibility analysis

MGSE

You can find more information about our services for MGSE here

QUALIFICATION

What special skills make us the ideal manufacturer of aerospace components?

Thin-walled parts

Aluminium and CFRP/GRP

Large-volume machining

You can find more information about our services in large-volume machining here.

CNC MANUFACTURING AVIATION AND AEROSPACE

Comprehensive customer service right from the start

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)