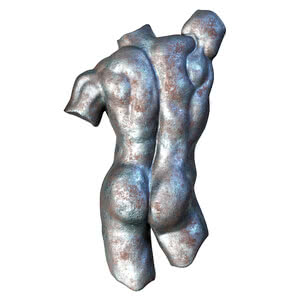

CNC art: Have 3D figures CNC-milled

- CNC machining to your exact specifications

- Simple and complex shapes

- Personalised advice for all process steps

3D milling for art | sculpture | architecture

Milling figures and contours: We are your partner for sophisticated CNC art

If you are an artist looking for a partner who can mould your ideas precisely, Laro NC-Technik is the right partner for you. We offer you the highest level of expertise paired with modern CNC machinery. With us, you can have CNC contours milled, 3D reliefs milled or complex sculptures and CNC figures milled. You can choose from various metals and non-metals. We machine small parts as well as special sizes up to 6,000 mm and 20 tonnes. We produce larger sculptures or architectural components in several individual parts that are assembled perfectly.

Laro NC-Technik stands for the highest quality and conscientiousness in production. This is proven by our EN 9100:2018 certification. We mill your components in special air-conditioned workshops to ensure maximum dimensional accuracy. We provide you with a dedicated contact person who will oversee your project and is always available to answer your questions and concerns. Our qualified team welcomes every new challenge and finds the right solution for every problem.

Laro NC-Technik stands for the highest quality and conscientiousness in production. This is proven by our EN 9100:2018 certification. We mill your components in special air-conditioned workshops to ensure maximum dimensional accuracy. We provide you with a dedicated contact person who will oversee your project and is always available to answer your questions and concerns. Our qualified team welcomes every new challenge and finds the right solution for every problem.

Service overview compact

| Category | Details |

|---|---|

| Materials | Aluminium, Steel/Stainless Steel, Titanium, Invar, CFRP, GFRP, Plastics |

| Part Size | up to 6000 mm |

| Part Weight | up to 20 t |

| Certification | EN 9100:2018 |

CNC 3D milling: We need this information from you

More than in the industrial sector, the individuality and uniqueness of the components take centre stage in art. Every CNC creative project requires its own approach. The more information you provide us with about the required moulded parts, the better we can meet your expectations. In the context of CNC art, the following information is particularly relevant:

Intended use and external influences

When we mill your CNC figures, we adapt them precisely to their intended use using the latest machining technology. For example, will they be displayed outdoors and exposed to the vagaries of nature? Especially in the field of architecture, where CNC contours are milled, 3D reliefs milled, wall panels milled or CNC facades milled, components must be correspondingly robust. We will be happy to advise you personally on the ideal properties of your components. Please note that components usually have to be checked by an external structural engineer beforehand.

Design data or 3D templates

If you have a finished CAD data set, this is of course the ideal prerequisite for production on our 3D milling machines. If the object has not yet been digitised, this is not a problem. In this case, we can call on experienced CNC creative specialists to produce a digital version using a 3D scan. This can then be milled from the material of your choice at the desired scale. The finished components always correspond precisely to your specifications. From simple to highly complex shapes, (almost) anything is possible thanks to state-of-the-art manufacturing processes. If you have any questions or problems with your design, our specialists will be happy to help. Where it makes sense, we will work with you to optimise your design for the best technical implementation.

Material selection

With us, you can choose from a wide range of materials. Each of them has different properties and a different aesthetic effect. The material has a significant impact on the properties of the CNC figures that are to be milled. We will be happy to advise you on the right choice of material.

Scheduling

As an industrial manufacturer of precision components, meeting deadlines is our top priority. Modern machines and short decision-making processes also enable us to provide express CNC production of your components at short notice. Let us know as early as possible when you need your CNC parts so that we can plan and deliver accordingly.

Enquire now without obligation and get advice!

Production Manager

Compact Machines

Markus Meschenmoser

+49 7558 930-502

Send e-mail

VCard downloaden (.vcf)

Compact Machines

Markus Meschenmoser

+49 7558 930-502

Send e-mail

VCard downloaden (.vcf)

CNC creative: Why have CNC figures milled by us?

✔ Consultancy

We passionately contribute our wide-ranging repertoire of skills, experience and know-how to your project.

We passionately contribute our wide-ranging repertoire of skills, experience and know-how to your project.

✔ Process chain

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

✔ Quality management

We supplement strict certification requirements with regard to quality, reliability and traceability with our personal ambition and commitment.

We supplement strict certification requirements with regard to quality, reliability and traceability with our personal ambition and commitment.

✔ Express milling

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

What are the advantages of CNC-milled figures "from one piece"?

The milling of components is a so-called separation process. Moulds are created by removing material from a solid block. This allows maximum freedom in the geometry of the manufactured parts. CNC machining is therefore very popular both in industry and in the artistic field. In addition, there are numerous advantages over other common manufacturing processes. The following table will give you an overview.

| Method | Typical Weaknesses | Advantage of CNC Milling |

|---|---|---|

CNC Turning | Limitations in shaping to regular geometry | Freeform surfaces and complex shaping possible |

Welding | Heat distortion/structural change at the weld seam | Comparatively low heat development |

3D Printing | Slow Frequent reworking necessary Metal structure often uneven | Fast express manufacturing usually no post-processing required |

Water Jet Cutting | Partially low cutting speed surface roughness | Fast express manufacturing |

Laser Cutting | Efficiency varies depending on material danger due to high temperature development | Reliable, rapid processing of all specified materials comparatively low heat development |

Metal Injection Molding | High costs limited economic efficiency, especially for large parts | Inexpensive economical for both small and large parts |

Sculpture CNC milling: How to create a project with Laro NC technology

We are not just a service provider for CNC machining. Our comprehensive 3D milling service offers all upstream and downstream work steps from a single source. All the services required for this are either available in-house or are carried out by affiliated companies. As your system supplier and partner, we support you in all work steps relating to 3D milling model making, CNC figure milling, 3D relief CNC milling and 3D sculpture milling.

Consultancy

We bring a wide range of expertise to your CNC art order. Our 3D milling/model making service includes a detailed discussion and consultation regarding your design or model. Specialists from various fields will work with you to find the optimum solution for your requirements. Our contact partners are available to answer your questions throughout the entire process.

Feasibility study

Unlike industrial orders, CNC creative projects focus on aesthetics and visual impact. Art projects are often unusual and crazy. This is where our feasibility analysis service is particularly useful. We save time, material and order costs by testing in advance how your idea can be realised in its current form. The production of your components is simulated in a virtual process in order to visualise potential challenges in advance. If necessary, we then develop an optimised production alternative - your artistic concept always remains in focus!

Machining

The high-precision CNC machining of your components is our main area of expertise. We mill a wide variety of materials precisely according to your requirements using automatic CNC milling machines. We realise simple shapes as well as highly complex and detailed art objects. Our modern and wide-ranging machine park has the right machine for every job.

Quality control

Our qualified personnel carry out a final inspection for each component. This ensures that all parts correspond exactly to the customer's requirements. Each component is automatically measured in the machine immediately after completion and then visually inspected by an experienced employee.

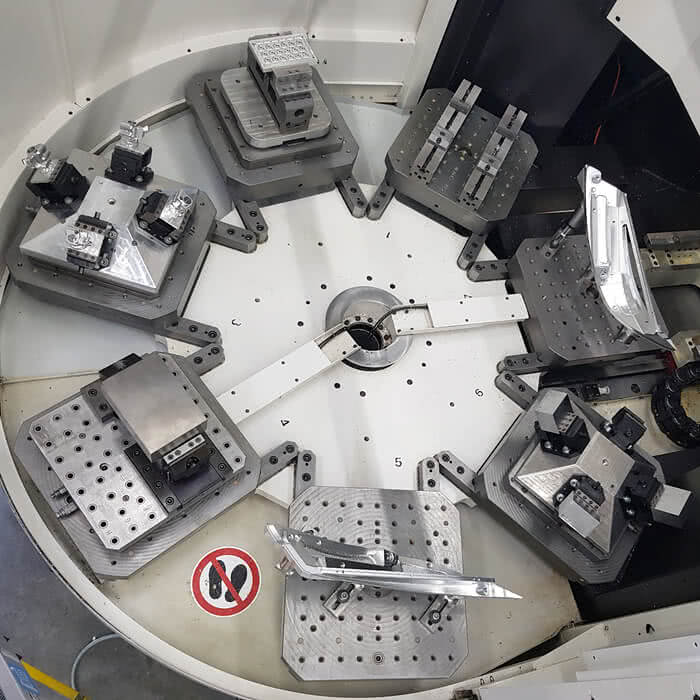

Round-the-clock production thanks to a high degree of automation

We use pallet changing systems to produce both series and individual parts fully automatically. We not only mill your components with the highest precision, but also efficiently and economically. This enables us to achieve maximum production quantities in the shortest possible time at favourable conditions. Alternatively, we can mill your one-off part practically overnight as an express order for punctual delivery.

From CNC art to architecture: We bring your idea into shape

With our modern 3D CNC milling machines, we support artists in the realisation of creative projects. No two orders are the same. The field of creative CNC machining can be roughly divided into the following areas:

Model making

Do you have a sculpture milled from plastic or metal in mind? We 3D mill figures exactly according to your ideas. As an artist or architect, you benefit from maximum flexibility in terms of design and material.

Architecture

We are also the right partner for the production of special and unusual architectural components. CNC-milled façades can be shaped in a complex manner. What's more, this type of production is particularly time-saving and economical. We offer you customised CNC architecture made from composite materials and various metals.

2D and 3D milling service

Visually appealing contours can be milled into various materials using CNC machining. With our modern machinery, we CNC mill contours that precisely meet your specifications. Our service includes CNC milling of free contours, CNC cut-outs with specific contours and filigree relief CNC structures.

Milling large parts to the perfect finish

Laro NC-Technik has invested in a 5-axis milling machine from FPT with Sinumerik One control. The quantum leap in terms of efficiency, precision and surface quality for machining large parts has been achieved and the course has been set for automated workpiece feeding.

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

Composite materials and metal: artistic CNC realisations with the right material

Choose from a total of seven different materials for the production of your moulded components.

- Steel/stainless steel: Steel is relatively easy to machine despite its high resistance, hardness and toughness. Steel components are often used in mechanical engineering and the construction industry, among others, due to their high strength.

- Aluminium: Aluminium offers high strength with low weight and high durability. Aluminium is used, for example, in electronics, engine and gearbox construction, aerospace and the construction industry.

- Titanium: Titanium is extremely durable with a relatively low density. It is a popular material for shipbuilding, outdoor equipment, aerospace, racing and construction parts of all kinds.

- Invar: This iron-nickel alloy offers particularly high length stability, even with temperature fluctuations. Invar is used, for example, in tanks for liquid gas ships, laser housings, RTM tools and astronomical instruments.

- CFRP: Carbon fibre reinforced plastics (CFRP) are characterised by high rigidity and low density. They are used, for example, in the manufacture of bicycle frames, aerospace and pressurised gas containers.

- GRP: Glass fibre reinforced plastics (GRP), also known as fibreglass, are cost-effective and at the same time very high quality. Their high elongation at break and elastic energy absorption make them the ideal material for the manufacture of leaf springs, small moulded parts, pipes and industrial doors, for example.

- Plastics: Plastics are particularly easy to machine. They are characterised by their versatility and low costs. They therefore play an important role in practically every branch of industry.

Comprehensive customer service right from the start

When it comes to CNC service, we are your worry-free full-service provider. Our range of services goes far beyond machining; we want to support you wherever you are.

From the initial idea to the finished component, we are the right partner for every project. You will be impressed by our customer-orientated company approach: fast response times, adherence to deadlines and openness to new ideas are just a few examples of what makes us stand out as a partner in machining. Our CNC milling services are affordable and reliable.

From the initial idea to the finished component, we are the right partner for every project. You will be impressed by our customer-orientated company approach: fast response times, adherence to deadlines and openness to new ideas are just a few examples of what makes us stand out as a partner in machining. Our CNC milling services are affordable and reliable.

Have we piqued your interest?

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)