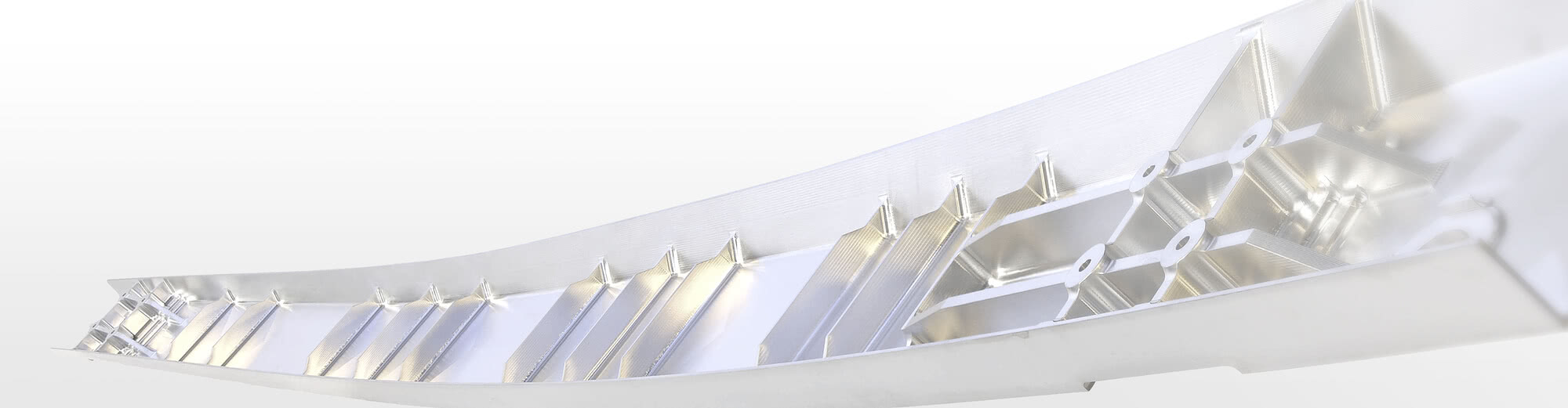

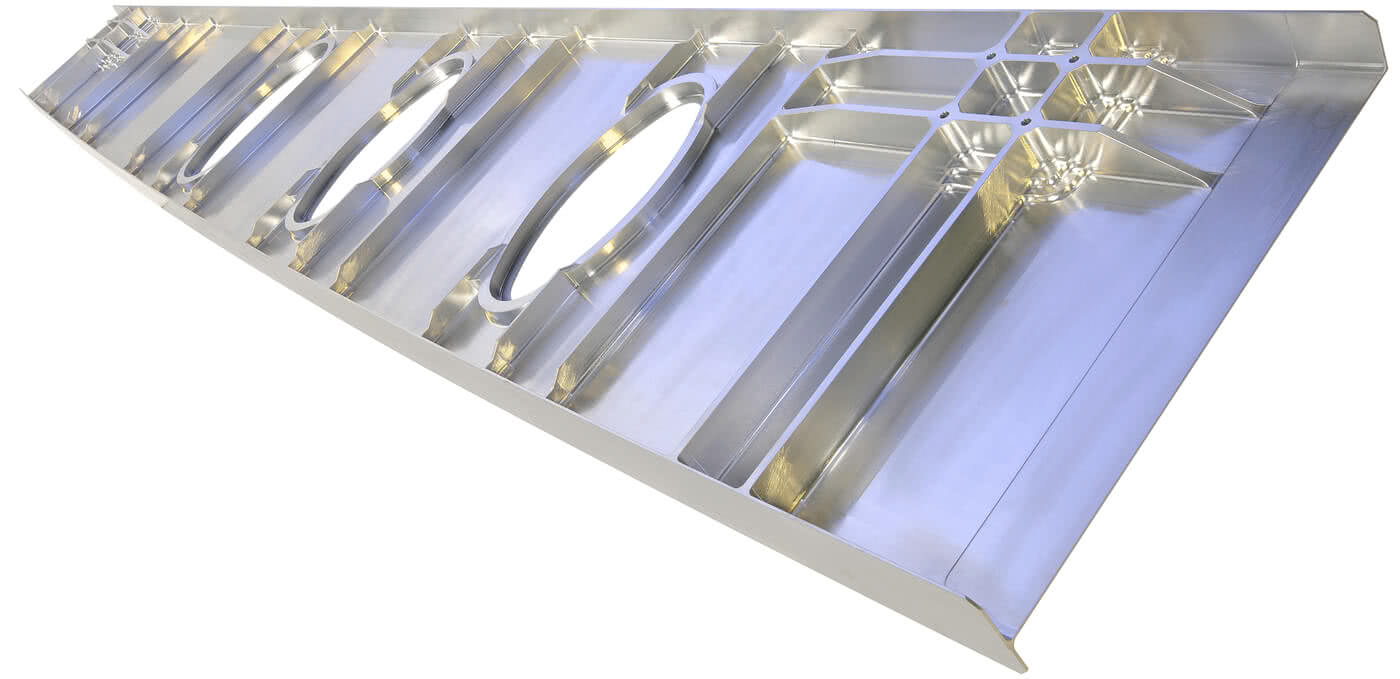

CNC milling of large parts for XXL projects

- Large part machining up to 6,000 mm and 20 tonnes

- Complex and thin-walled large parts without any weld seams or connecting parts

- Various materials and alloys in steel, aluminium, titanium, Invar, composite materials, plastics

- Expert advice and high-speed cutting milling service for large-scale machining

CNC large-scale machining

✔ Feasibility study

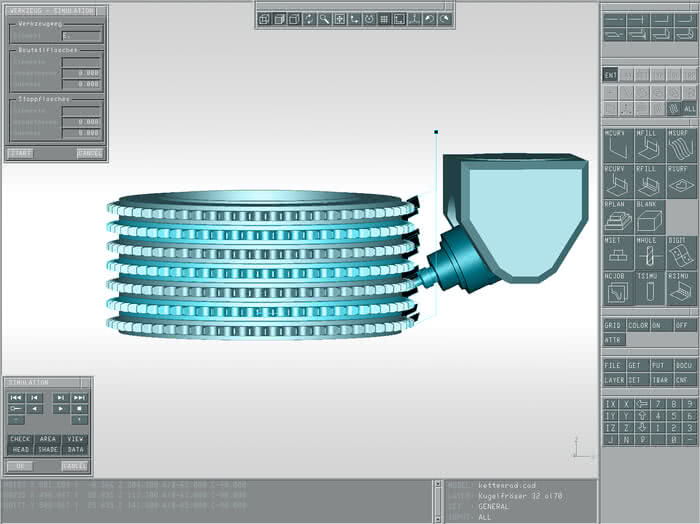

Virtual machines allow the complete simulation of the machining processes before the actual manufacturing stage in order to achieve optimisation and material savings.

Virtual machines allow the complete simulation of the machining processes before the actual manufacturing stage in order to achieve optimisation and material savings.

✔ Air-conditioned production

Air-conditioned production halls guarantee absolute dimensional accuracy of the manufactured parts.

Air-conditioned production halls guarantee absolute dimensional accuracy of the manufactured parts.

✔ EN 9100 certified

Certified CNC service in accordance with the strict requirements of DIN EN 9100:2018 for the aerospace sector.

Certified CNC service in accordance with the strict requirements of DIN EN 9100:2018 for the aerospace sector.

✔ Aerospace industry

We manufacture components for the aerospace sector as well as ultra-lightweight parts in accordance with DIN EN 9100:2018.

We manufacture components for the aerospace sector as well as ultra-lightweight parts in accordance with DIN EN 9100:2018.

Milling large parts to the perfect finish

Laro NC-Technik has invested in a 5-axis milling machine from FPT with Sinumerik One control. The quantum leap in terms of efficiency, precision and surface quality for machining large parts has been achieved and the course has been set for automated workpiece feeding.

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

HIGHEND HEAVY DUTY MILLING by Laro NC-Technik

Contract manufacturing Milling of large parts to perfection

Are you looking for cost-effective and qualified contract milling of large parts? Laro NC-Technik is the generalist in the field of high-speed heavy-duty cutting. We have the expertise and high-performance cutting tools to mill even oversized parts at high speed. Our contract manufacturing offers milling of large parts up to 6,000 mm long | 3,500 mm wide | 1,500 mm high and weighing up to 20 tonnes. The machining of large parts is carried out in air-conditioned workshops and in strict compliance with the EN 9100 and ISO 9001 quality certificates.

The majority of our machining processes steel, aluminium, titanium, Invar, CFRP/GRP and various plastics. In addition, we offer all process steps from design to the finished component. All the necessary technologies and machines for heavy-duty machining are available in-house on our company premises. This means that you always receive all services from a single source. We are on hand to advise you throughout the entire production process for large-volume machining.

We use modern virtualisation methods to optimise designs and travel paths before we mill the large parts. In this way, we also guarantee particularly reliable production processes. Our experienced employees find the optimum solution for every project. You will notice their high level of motivation and expertise from the very first meeting.

We are always open to new ideas and determined to fulfil your requirements in every respect. High dimensional accuracy and customer-orientation make Laro NC-Technik the ideal partner for contract manufacturing in heavy-duty machining throughout Europe.

The majority of our machining processes steel, aluminium, titanium, Invar, CFRP/GRP and various plastics. In addition, we offer all process steps from design to the finished component. All the necessary technologies and machines for heavy-duty machining are available in-house on our company premises. This means that you always receive all services from a single source. We are on hand to advise you throughout the entire production process for large-volume machining.

We use modern virtualisation methods to optimise designs and travel paths before we mill the large parts. In this way, we also guarantee particularly reliable production processes. Our experienced employees find the optimum solution for every project. You will notice their high level of motivation and expertise from the very first meeting.

We are always open to new ideas and determined to fulfil your requirements in every respect. High dimensional accuracy and customer-orientation make Laro NC-Technik the ideal partner for contract manufacturing in heavy-duty machining throughout Europe.

Enquire now without obligation and get advice!

LARGE PART MILLING

What are the particular challenges of CNC machining large parts?

Rely on our expertise and reliability for the machining of large parts. Milling large parts requires special expertise and exceptional machinery. With High Performance Cutting (HPC), we rough large blocks of material in the shortest possible time. In the subsequent High Speed Cutting (HSC) process, we produce a high-quality surface finish in record time that requires no post-processing. We use consistent process reliability and high-quality production to ensure that the end result meets your exact requirements.

Your project is in the best hands with us. Our company is excellently equipped for heavy-duty machining and milling . We fulfil all the requirements for contract manufacturing when milling your large parts. We summarise the most important points for you here:

Your project is in the best hands with us. Our company is excellently equipped for heavy-duty machining and milling . We fulfil all the requirements for contract manufacturing when milling your large parts. We summarise the most important points for you here:

CNC machinery: Plenty of workspace for large-volume machining

Not all milling machines are the same. The maximum size of the parts to be machined is clearly defined for each CNC machine. Many companies rely on machines that only allow the machining of common part sizes, as this is often more profitable. However, if you want to mill large parts for your project, Laro NC-Technik GmbH is the right partner for you as a particularly broad-based supplier. With our modern and powerful CNC machines, machining large parts is no problem. The machining of large parts up to 6,000 mm and 20 tonnes is our everyday business. You can rely on precise and safe CNC machining of large parts in our air-conditioned halls.

FPT DINO MAX

High Performance Cutting

High Speed Cutting

Working area X = 6000mm, Y = 3500mm, Z = 1500mm

High Performance Cutting

High Speed Cutting

Working area X = 6000mm, Y = 3500mm, Z = 1500mm

Henri-Line Vertamill 229 Zoom

Working area X = 6000mm, Y = 2850mm, Z = 2100mm

Working area X = 6000mm, Y = 2850mm, Z = 2100mm

Bavius UBZ HP 300/200 T3

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

Bavius UBZ NT 300/200

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

Bavius UBZ NT 300/200

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

FPT Dino

Working area X = 2300mm, Y = 1600mm, Z = 900mm

Working area X = 2300mm, Y = 1600mm, Z = 900mm

Expertise and experience: Heavy-duty machining/milling is our thing

However, having the right equipment is not enough: CNC machining of large parts requires special expertise and decades of project experience. Our qualified employees are able to machine large parts with the highest precision. Our special experience and expertise make us experts in CNC milling work on large parts. We also ensure maximum dimensional accuracy for workpiece dimensions that are far removed from the usual standard sizes. You receive a product that exactly meets your expectations.

Maximum efficiency: Making large-part machining economical

CNC milling work on large parts is usually more complex than for standard sizes. Nevertheless, it is our aim to offer you the highest quality at a fair price. Especially when milling large parts, you as a customer benefit from our particularly reliable production processes thanks to modern visualisation methods. Even if we are not the milling shop near you or your location, you can rely on the quality promise of Laro NC Technik without having to be on site yourself. We guarantee that.

This allows us to detect challenges or potential difficulties in machining large parts in advance and identify possible solutions. Without the costly use of material and machines, we analyse and optimise your designs - cost-saving and reliable.

This allows us to detect challenges or potential difficulties in machining large parts in advance and identify possible solutions. Without the costly use of material and machines, we analyse and optimise your designs - cost-saving and reliable.

CNC LARGE PARTS MACHINING

What special skills characterise us for milling large parts?

Decide in favour of Laro NC-Technik GmbH for the milling of large parts: We also support you in all upstream and downstream work steps. For example, you can save considerable transport costs for large components by having assembly, measuring and finishing carried out directly by us. You receive all services from a single source. As an EN 9100:2018-certified company, the highest quality is our claim and standard.

Performance overview CNC milling of large parts

| CNC Milling Metals | Steel, Aluminium, Titan, Invar |

|---|---|

| CNC Milling Non-Metals | CFRP, GFRP, various plastics |

| Workpiece Length | up to 6000 mm |

| Weight | up to 20 t |

| Certification | EN 9100:2018 |

High precision in large-scale machining thanks to air-conditioned production halls

We always manufacture your large components in specially designed, air-conditioned production halls. The heat generated by the high-speed cutting tools during operation is dissipated directly. By maintaining constant temperatures, the large CNC parts retain their exact dimensions and properties throughout the entire machining process. This is because the larger the aluminium block, the greater the effect of material expansion due to temperature fluctuations during CNC milling. Without air conditioning, large parts could grow or shrink by several millimetres during machining. In our world of high precision, this is a no-go for machining large parts!

HEAVY MACHINING STARTS WITH CONSULTATION

Comprehensive customer service from the idea to the finish

When it comes to large-volume machining, we are your worry-free full-service provider for CNC milling large parts. Our range of services goes far beyond machining; rather, we want to support you wherever you are. From the idea to the finished component, we are the right partner for every project in the mechanical processing of your large parts.

You will be impressed by our customer-orientated company approach: fast response times, adherence to deadlines and openness to new ideas are just a few examples of what makes us stand out as a partner in machining. Our CNC milling services are reasonably priced and reliable.

You will be impressed by our customer-orientated company approach: fast response times, adherence to deadlines and openness to new ideas are just a few examples of what makes us stand out as a partner in machining. Our CNC milling services are reasonably priced and reliable.

Have we piqued your interest?

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)