CNC machining for MRO Services Aviation

- 100% Made in Germany

- Guaranteed confidentiality & highest safety standards

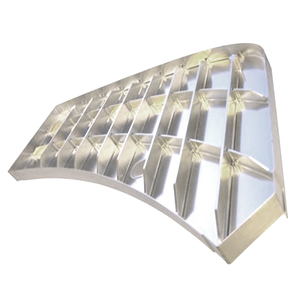

- Highest precision even for particularly complex components

- Special expertise for large thin-walled parts

- Express manufacturing & automated 24/7 production

Laro NC-Technik: MRO spare parts manufacturer for aircraft maintenance

EN 9100 certification

Certified CNC service in accordance with the strict requirements of DIN EN 9100:2018 for the aerospace sector.

Certified CNC service in accordance with the strict requirements of DIN EN 9100:2018 for the aerospace sector.

✔ Express service

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

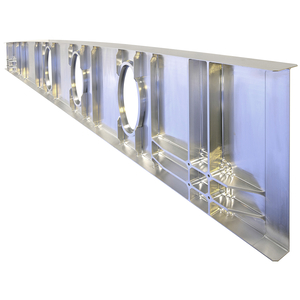

✔ High-volume machining

Our measurement sizes enable HPC/HSC milling of large parts with lengths up to 6,000 mm and weights up to 20 tons.

Our measurement sizes enable HPC/HSC milling of large parts with lengths up to 6,000 mm and weights up to 20 tons.

✔ Air-conditioned production

Air-conditioned production halls guarantee absolute dimensional accuracy of the manufactured parts.

Air-conditioned production halls guarantee absolute dimensional accuracy of the manufactured parts.

MRO AVIATION SPARE PARTS MILLING

What distinguishes us as a manufacturing partner for aircraft maintenance?

The aviation industry relies on ongoing maintenance, repair and overhaul (MRO) to ensure the safety and efficiency of its fleets. Laro NC-Technik manufactures high-precision milled parts for aircraft in accordance with the EN 9100:2018 standard. With our special experience in lightweight construction, we are able to mill high-quality parts from aluminium, steel, titanium, Invar and various plastics.

We apply the high standards of the aviation industry on a daily basis, which are required by aviation MRO throughout Europe. We are therefore very familiar with the typical requirements in this area. We manufacture high-quality and dimensionally accurate milled parts and assemblies for aircraft maintenance and repair. Our employees look forward to every new challenge and your customised project!

As a generalist CNC service provider, we provide you with all services from a single source. Depending on your requirements, we can also take on individual upstream or downstream work steps, such as surface finishing, in addition to machining. We even consistently "think along" with the process steps outside our company. Because we want to support you as effectively as possible in the realisation of your project.

Our wide-ranging expertise and modern machinery make us the ideal partner for all cases. Convince yourself of the expertise and commitment of our employees.

Make an appointment now for a non-binding consultation!

We apply the high standards of the aviation industry on a daily basis, which are required by aviation MRO throughout Europe. We are therefore very familiar with the typical requirements in this area. We manufacture high-quality and dimensionally accurate milled parts and assemblies for aircraft maintenance and repair. Our employees look forward to every new challenge and your customised project!

As a generalist CNC service provider, we provide you with all services from a single source. Depending on your requirements, we can also take on individual upstream or downstream work steps, such as surface finishing, in addition to machining. We even consistently "think along" with the process steps outside our company. Because we want to support you as effectively as possible in the realisation of your project.

Our wide-ranging expertise and modern machinery make us the ideal partner for all cases. Convince yourself of the expertise and commitment of our employees.

Make an appointment now for a non-binding consultation!

Expertise and speed in MRO spare parts production

Quality and precision

The quality and precision of the CNC milled parts produced by Laro NC-Technik are unrivalled. The company utilises state-of-the-art technology and machinery to ensure that every part meets the highest standards in the aerospace industry. This ensures not only the safety but also the longevity of the components.

Short delivery times

One of Laro NC-Technik's USPs is its ability to guarantee short delivery times thanks to automated 24/7 CNC production. Thanks to efficient production planning and automatic palletising systems, the company can mill and deliver the required spare parts in the shortest possible time. Our Aircraft MRO customers benefit from minimised downtimes and optimised maintenance processes.

Flexibility and adaptability

Laro NC-Technik understands the individual requirements of the aviation industry and offers customised solutions for aviation MRO. Whether special materials, complex geometries or special surface treatments are involved: The company is able to adapt to the specific needs of the MRO Aviation Industry and deliver high quality products.

WIDE RANGE OF TITANIUM AND ALUMINIUM ALLOYS

The right material for every spare part

The material requirements for spare parts in aircraft maintenance are extremely strict and specific in order to ensure the safety and reliability of aircraft fleets. The materials used must match the design characteristics of the original part, be corrosion resistant and durable. Laro NC-Technik can mill almost all of the metals required in aviation. Regular tests and certifications ensure that Laro NC-Technik manufactures and documents every spare part in accordance with the aviation industry's EN 9100 requirements.

| Metal | Material designation | Properties |

|---|---|---|

Titanium Alloys | Ti-6Al-4V, Ti-6AL-4V ELI, 6AL-6V-2Sn-Ti | High strength, low weight, corrosion resistance, high cycle fatigue resistance - used in aerospace, maritime, chemical industry, biomedical applications |

Aluminium Alloys with Copper | EN AW 2099, EN AW 2196, EN AW 2618 | High strength, prone to corrosion, mostly difficult or not weldable - used in aircraft and aerospace |

Aluminium Alloys with Magnesium | EN AW 5754, EN AW 5083 | Medium to high strength, weldable - used in shipbuilding, transport, pressure vessels, bridges and buildings, as AA5024 (AlMgSc) also for aerospace applications |

Aluminium Alloys with Magnesium + Silicon | EN AW 6082, EN AW 6060, EN AW 6061 | Very weldable and extrudable - mainly used as extruded profiles |

Aluminium Alloys with Zinc | EN AW 7010, EN AW 7019, EN AW 7020, EN AW 7040, EN AW 7050, EN AW 7074, EN AW 7075 | High to very high strength - used in aircraft, aerospace, sports equipment, mobile phone and watch cases |

Invar (Iron-Nickel Alloy) | 1.3912 | High dimensional stability under temperature fluctuations – used in aircraft construction, aerospace engineering, shipbuilding, electronics, and laser housings |

What sets Laro NC-Technik apart are its experienced and qualified employees with comprehensive material expertise, its modern machinery and its customer-orientated company focus. This enables us to fulfil your individual requirements. You can rely on our competence and expertise in the production of MRO aviation spare parts. High-speed cutting (HSC milling) enables aviation parts to be manufactured particularly quickly. From thin-walled, lightweight workpieces to heavy-duty machining: we manufacture highly complex components and guarantee end-to-end process reliability.

Range of surface coating / surface finishing services

- Glass bead blasting

- Powder coating

- Painting

- Passivation

- Anodising

- Silver plating

- Nickel plating

- Galvanising

- Chromic acid anodising

- Hard anodising

- Copper plating

- Chrome plating

- Gold plating

CNC machinery: plenty of workspace for large-volume machining

If you would like to have large, thin-walled components milled, Laro NC-Technik GmbH is the right partner for you as a particularly broad-based supplier. With our modern and powerful CNC machines, machining large parts is no problem. Machining large parts up to 6,000 mm and 20 tonnes is part of our everyday business. You can rely on precise and safe CNC machining of large parts in our air-conditioned halls.

FPT DINO MAX

High Performance Cutting

High Speed Cutting

Working area X = 6000mm, Y = 3500mm, Z = 1500mm

High Performance Cutting

High Speed Cutting

Working area X = 6000mm, Y = 3500mm, Z = 1500mm

Henri-Line Vertamill 229 Zoom

Working area X = 6000mm, Y = 2850mm, Z = 2100mm

Working area X = 6000mm, Y = 2850mm, Z = 2100mm

Bavius UBZ HP 300/200 T3

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

Bavius UBZ NT 300/200

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

Bavius UBZ NT 300/200

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

FPT Dino

Working area X = 2300mm, Y = 1600mm, Z = 900mm

Working area X = 2300mm, Y = 1600mm, Z = 900mm

Expertise in CNC contract manufacturing of titanium and aluminium aircraft components

Benefit from our many years of experience as a versatile CNC service provider. Our broad and in-depth expertise in many areas of machining makes us ideally qualified for the production of highly complex parts. We have also been milling unusual and particularly demanding components in the aviation sector for many years.

Aviation Engine MRO

In aircraft engine maintenance, the blades and vanes of the compressor, combustion chamber linings, thermal shields, bearings and seals, engine cowlings, sensors and control units are tested for function and wear.

Aircraft Landing Gear MRO

During every landing, enormous forces act on the landing gear of an aircraft, especially the wheels and tyres. During maintenance, full attention is also paid to brake pads, brake discs, shock absorbers, springs, axles, bearings, hydraulic lines and valves, speed and position sensors.

Aircraft Component MRO

Typical wear parts in the structure and aircraft hull include panelling and covers, windows and doors, maintenance hatches, inspection openings, reinforcement plates, frames, brackets and fasteners.

AIRCRAFT COMPONENT MRO MANUFACTURING

Comprehensive customer service for professional aircraft maintenance

The aviation industry depends on efficient and reliable MRO services to ensure the safety and operational readiness of their fleets. Laro NC-Technik offers MRO Services Aviation the competent and fast production of CNC milled parts. By combining quality, precision, material diversity and flexibility, Laro NC-Technik offers customised solutions that meet the high demands of aviation MRO.

Have we piqued your interest?

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)

You might also be interested in:

Aircraft components

Helicopter components