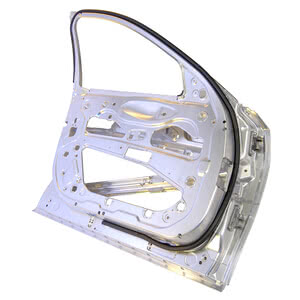

Cubing model for automotive and design brought into shape

- Complex cubing models for every industry

- Highest precision and best quality

- Customised advice and all services from a single source

Our range of services for cubing models:

CUBING QUALITY

We are your flexible partner for cubing models

You've come to the right place for high-quality illustrative models of all kinds. Use our precisely milled cubing models to optimise components or for presentation purposes. We take your requirements and wishes into account down to the smallest detail. You will only receive components from us that exactly meet your expectations.

No matter where you are right now: we will pick you up and help you make progress with your project. Laro NC-Technik is an all-round provider of high-end CNC machining. We have the right solution for practically every challenge. What sets us apart, however, is our high level of customer orientation.

Convince yourself of the high quality of our advice and our willingness to talk.

Make an appointment now for a non-binding consultation!

We also offer the production of fully functional prototypes.

You can find out more about our prototyping services here.

No matter where you are right now: we will pick you up and help you make progress with your project. Laro NC-Technik is an all-round provider of high-end CNC machining. We have the right solution for practically every challenge. What sets us apart, however, is our high level of customer orientation.

Convince yourself of the high quality of our advice and our willingness to talk.

Make an appointment now for a non-binding consultation!

We also offer the production of fully functional prototypes.

You can find out more about our prototyping services here.

Milling large parts to the perfect finish

Laro NC-Technik has invested in a 5-axis milling machine from FPT with Sinumerik One control. The quantum leap in terms of efficiency, precision and surface quality for machining large parts has been achieved and the course has been set for automated workpiece feeding.

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

WORRY-FREE FULL-SERVICE PROVIDER

How do we ensure maximum satisfaction among our cubing model customers?

Your cubing models must not only fulfil their purpose. They should be durable and robust, as well as flexible and inexpensive to produce. We fulfil all these requirements as part of our modern contract manufacturing. Benefit from our qualified employees and state-of-the-art machinery.

Every cubing model is similar in principle, yet unique. That's why we customise our approach to you and your project. The following points in particular characterise our production of cubing models:

Every cubing model is similar in principle, yet unique. That's why we customise our approach to you and your project. The following points in particular characterise our production of cubing models:

- Maximum flexibility in services and delivery schedules

- Good availability

- Fast internal decision-making

- High reliability

- Tangible employee commitment across all process steps

With us, you get more than just CNC services. We see ourselves as your partner. Accordingly, we consistently consider all work steps and also think "outside the box". Our qualified employees are highly motivated to fulfil your requirements in every respect.

CUBING FOR AUTOMOTIVE & CO.

Where are cubing models used?

Cubing models, i.e. purely illustrative models without functionality, are used in many areas of industry. As a rule, these are real-size models. They are an inexpensive way of optimising components or experimenting with them. Cubing models are very flexible in their use due to their freely selectable properties. They can be easily customised to meet specific requirements.

Cubing for cars: We specialise in cubing models for the automotive industry

In the highly competitive automotive industry, cubing models are an excellent way of cost-effectively improving components. This applies not only to technical aspects. More than in almost any other industry, the appearance of the finished product is of particular importance for cars. Test cubings enable designers and technical staff alike to identify any potential for improvement.

We have extensive experience in the field of automotive cubing in particular. We realise your cubing car models quickly, reliably and cost-effectively. We provide insights into our production processes for cubing automotive models in the specialist magazine for metalworking "fertigung".

Find out more about our commitment to precision and top quality in the "fertigung" magazine article:

Cubing model production - open for automation

We have extensive experience in the field of automotive cubing in particular. We realise your cubing car models quickly, reliably and cost-effectively. We provide insights into our production processes for cubing automotive models in the specialist magazine for metalworking "fertigung".

Find out more about our commitment to precision and top quality in the "fertigung" magazine article:

Cubing model production - open for automation

YOUR CUBING PARTNER

Comprehensive customer service right from the start

When it comes to CNC service, we are your worry-free full-service provider. Our range of services goes far beyond machining. Rather, we want to support you wherever you are. From the initial idea to the finished component, we are the right partner for every project. Our CNC milling services are affordable and reliable.

Have we piqued your interest?

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)