CNC milling customised production: Your unique piece in EN 9100 quality

- High-quality and reliable CNC customised production

- Process reliability through feasibility analysis and CNC simulator

- All upstream and downstream process steps from a single source

- Personalised advice and competent contact partners

Contract manufacturing CNC single parts

HAVE INDIVIDUAL PARTS MILLEDYour advantages with Laro NC technology

Welcome to the contract manufacturer for your CNC single-part production! We mill individual parts quickly and cost-effectively. With our advanced and versatile machinery, we can also fulfil demanding orders on time.

We are happy to support you in the creation and optimisation of your design data for CNC single-part production. Of course, we will advise you individually on all process steps. Solution expertise and flexibility are what count in high-end CNC production for individual parts. We combine these characteristics with excellent manufacturing quality. Our qualified employees will also find the optimum solution for your project.

We are happy to support you in the creation and optimisation of your design data for CNC single-part production. Of course, we will advise you individually on all process steps. Solution expertise and flexibility are what count in high-end CNC production for individual parts. We combine these characteristics with excellent manufacturing quality. Our qualified employees will also find the optimum solution for your project.

Experience & expertise

Laro NC-Technik milling shop has extensive project experience and detailed expertise in the field of high-precision CNC milling. Our customers include the aerospace industry, but also any other sector in which complex and precise milled parts are required.

Laro NC-Technik milling shop has extensive project experience and detailed expertise in the field of high-precision CNC milling. Our customers include the aerospace industry, but also any other sector in which complex and precise milled parts are required.

Machinery

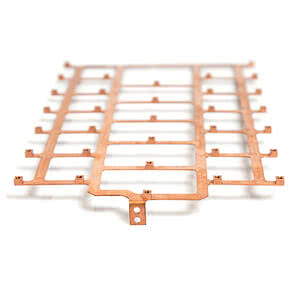

Our modern and excellently equipped machine park. Palletising systems enable us to offer 24/7 CNC production. The large traverse path of our high-speed cutting milling machines allows us to machine objects measuring up to 6 x 3.5 x 1.5 metres. We CNC-mill individual parts ranging from small filigree copper grids to huge aircraft tank stiffeners.

Our modern and excellently equipped machine park. Palletising systems enable us to offer 24/7 CNC production. The large traverse path of our high-speed cutting milling machines allows us to machine objects measuring up to 6 x 3.5 x 1.5 metres. We CNC-mill individual parts ranging from small filigree copper grids to huge aircraft tank stiffeners.

Variety of materials

You can have individual parts milled by us from a wide range of materials: from aluminium to stainless steel, high-strength steel, Invar, GRP, CFRP and various plastics through to titanium. Laro NC-Technik is one of the leading CNC milling companies with extensive project experience, particularly when it comes to titanium.

You can have individual parts milled by us from a wide range of materials: from aluminium to stainless steel, high-strength steel, Invar, GRP, CFRP and various plastics through to titanium. Laro NC-Technik is one of the leading CNC milling companies with extensive project experience, particularly when it comes to titanium.

Quality level EN 9100

The strict quality controls required by our regular certification to the EN 9100:2018 standard ensure that the individual CNC parts produced meet your specifications exactly at every stage of the process.

The strict quality controls required by our regular certification to the EN 9100:2018 standard ensure that the individual CNC parts produced meet your specifications exactly at every stage of the process.

Flexibility & communication

At Laro NC-Technik, you have a dedicated contact partner throughout all project phases. We respond individually and flexibly to your requirements and attach great importance to good communication. This is particularly important for customised products in order to quickly achieve the perfect result based on our experience, virtual simulation and rapid prototyping.

At Laro NC-Technik, you have a dedicated contact partner throughout all project phases. We respond individually and flexibly to your requirements and attach great importance to good communication. This is particularly important for customised products in order to quickly achieve the perfect result based on our experience, virtual simulation and rapid prototyping.

Surfaces & assemblies

We offer additional services such as surface treatments, component assembly and prototype development . In this way, we aim to make the entire production process, right up to the CNC individual part, as efficient as possible for you as a customer.

We offer additional services such as surface treatments, component assembly and prototype development . In this way, we aim to make the entire production process, right up to the CNC individual part, as efficient as possible for you as a customer.

CNC MILLING: CUSTOMISED PRODUCTION FOR THE HIGHEST DEMANDS

Laro NC-Technik stands for the highest precision and quality in CNC customised production. With state-of-the-art technology and a highly qualified team, CNC single-part production is one of our areas of specialisation in which we can meet even the most demanding requirements. You can rely on our many years of experience and our commitment to quality to successfully realise your projects:

- Creation and optimisation of design plans

- Good accessibility and communication quality

- Feasibility analyses using virtual production

- Seamless documentation and traceability

- A wealth of experience in various specialised areas of machining

- Air-conditioned production halls

- Continuous process reliability

MILLING A SINGLE CNC PART?We are your contact!

As your partner in CNC single-part production, we attach great importance to the rapid realisation of your requirements. We know that changes can often occur during the course of a project. We also routinely incorporate subsequent changes to your designs for your CNC single part.

Our high standards in terms of customer-orientation and flexibility:

Our high standards in terms of customer-orientation and flexibility:

- Flat company hierarchy for particularly short decision-making paths

- Employees are open to new ideas and motivated by special challenges

- Fast response to enquiries, urgent orders and change requests

- Flexible delivery scheduling

- One contact person for the entire order

- Range of services also includes all secondary services from design to final inspection

Milling large parts to the perfect finish

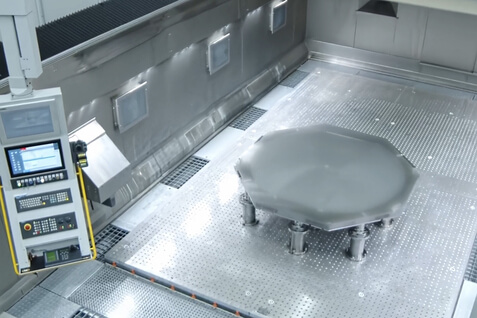

Laro NC-Technik has invested in a 5-axis milling machine from FPT with Sinumerik One control. The quantum leap in terms of efficiency, precision and surface quality for machining large parts has been achieved and the course has been set for automated workpiece feeding.

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

CNC SINGLE PART MACHININGOur comprehensive customer service right from the start

When it comes to CNC service, we are your worry-free full-service provider. Our range of services goes far beyond machining; we want to support you wherever you are. From the initial idea to the finished component, we are the right partner for every project. Our CNC milling services are affordable and reliable.

Have we piqued your interest?

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)