High-end CNC contract manufacturing and engineering

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

Our measurement sizes enable HPC/HSC milling of large parts with lengths up to 6,000 mm and weights up to 20 tons.

Air-conditioned production halls guarantee absolute dimensional accuracy of the manufactured parts.

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

We manufacture components for the aerospace sector as well as ultra-lightweight parts in accordance with DIN EN 9100:2018.

The materials machined in the CNC milling shop are aluminium, steel, titanium, GRP and CFRP, as well as various composite materials. By using HMS compensation (Head Measuring System), we guarantee maximum dimensional accuracy of the contours.

Our range of services in CNC machining

Laro Full Service

- Engineering

- Construction

- Machining

- Assembly

- Finish

- Inspection

Give your design a shape. We find the optimum solution for all CNC contract manufacturing orders. With our modules and expertise, we maximise the efficiency of the process chain from the CAD model to the finished component.

Learn more

Virtual machines

- CNC Simulator

- Reliable machining process

- Feasibility analyses

We use modern virtualisation methods to optimise designs in advance. In this way, we not only guarantee particularly reliable production processes. Computer-aided simulation makes it possible to test the feasibility of a part as early as the planning phase without wasting material.

EN 9100 certified

- Aviation components

- Aerospace components

- Assemblies

- Ultra lightweight construction

- Finish

- Inspection

For your aerospace project, we offer you CNC components that are lightweight and cost-effective. Our high-quality components can withstand even extreme conditions. They meet the highest standards in terms of quality and reliability.

Learn more

Milling large parts to the perfect finish

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

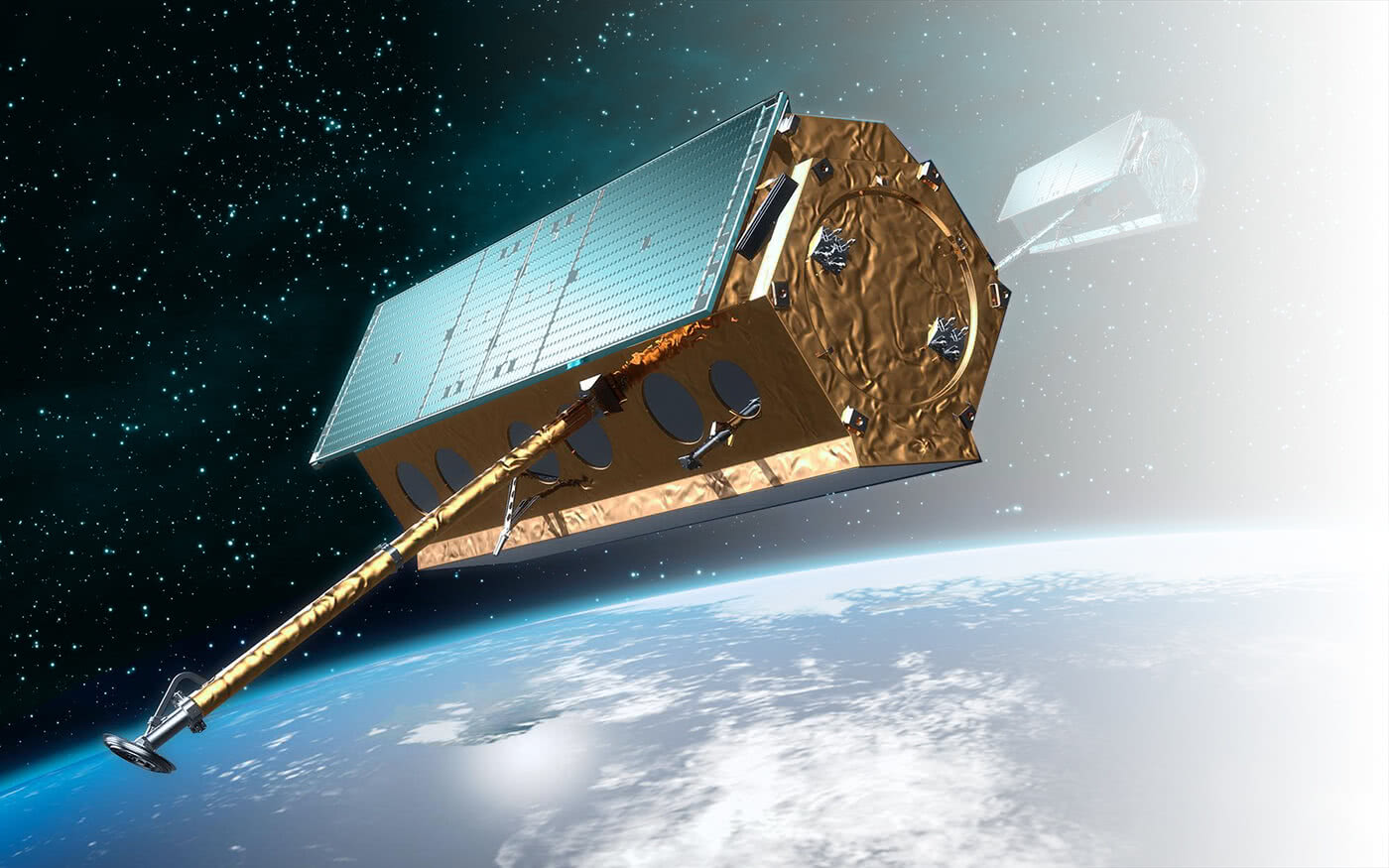

Our post of the week

The MetOp satellite is one of a series of three polar-orbiting meteorological 🛰️Satelliten satellites developed by the European Space Agency (ESA) and operated by the European Organisation for the Exploitation of Meteorological Satellites (EUMETSAT). The MetOp satellites carry a payload of 11 scientific instruments and two instruments that support the Cospas-Sarsat search and rescue services.

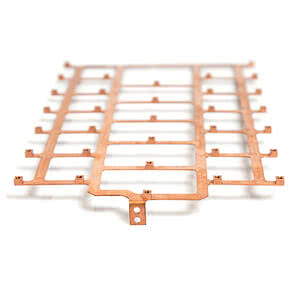

Several Laro NC machined aluminium ⚙️Mounting brackets play a literal supporting role in the construction and mounting of these satellite components. These brackets offer an optimal balance between strength and weight. Special aluminium alloys are particularly suitable for applications that require high precision and resilience, such as the mounting of scientific 📡instruments, sensors and solar modules.

For high-strength mounts that ensure MetOp-SG keeps an eye on the weather.

Which components would you like to keep under control?

Talk to us about your project - we will be happy to advise you!

Tobias Kreft | Sales ✆ +49 7558 930-514

Tobias Kreft

Talk to me about your project - we will be happy to advise you!

I look forward to your call: