Laro NC technology machine list

Our core expertise includes the milling of sophisticated moulds, whether individual parts, assemblies, small series or panels. Additional tasks are also carried out, from design to assembly. As a system supplier, we manufacture models and moulds for many industries, including the aerospace industry, for example.

The final inspection in the climate-controlled QA is of course also part of the broad Laro portfolio.

Give shape - gain form!

The final inspection in the climate-controlled QA is of course also part of the broad Laro portfolio.

Give shape - gain form!

FPT DINO MAX

High Performance Cutting | High Speed Cutting

Working area X = 6000mm Y = 3500mm Z = 1500mm

Start interactive 360° view

High Performance Cutting | High Speed Cutting

Working area X = 6000mm Y = 3500mm Z = 1500mm

Start interactive 360° view

Henri-Line Vertamill 229 Zoom

Working area X = 6000mm, Y = 2850mm, Z = 2100mm

Working area X = 6000mm, Y = 2850mm, Z = 2100mm

Bavius UBZ HP 300/200 T3

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

FPT Dino

Working area X = 2300mm, Y = 1200mm, Z = 900mm

Working area X = 2300mm, Y = 1200mm, Z = 900mm

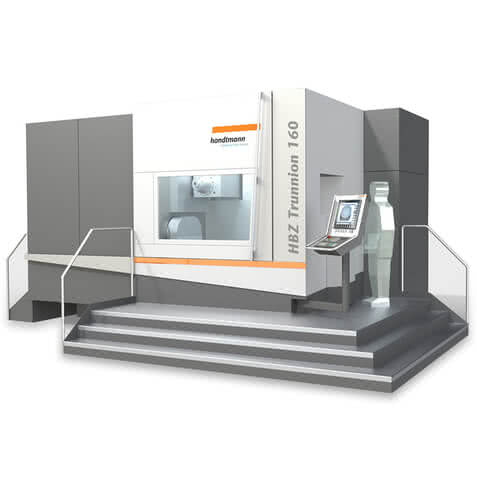

Bavius HBZ TR160

Working area X = 1600mm, Y = 1350mm, Z = 1100mm

Working area X = 1600mm, Y = 1350mm, Z = 1100mm

Mikron HPM 1000U

Working area X = 1000mm, Y = 800mm, Z = 600mm

Working area X = 1000mm, Y = 800mm, Z = 600mm

Bavius HBZ TR80

Working area X = 850mm, Y = 850mm, Z = 700mm

Working area X = 850mm, Y = 850mm, Z = 700mm

DMU 100T

Working area X = 1080mm, Y = 710mm, Z = 710mm

Working area X = 1080mm, Y = 710mm, Z = 710mm

DMU 70eVo

Working space X = 750mm, Y = 600mm, Z = 520mm

Working space X = 750mm, Y = 600mm, Z = 520mm