CNC milled parts for the shipbuilding and offshore supply industry

In shipbuilding and for offshore installations, special requirements apply to metals and plastics in terms of corrosion resistance, but also resilience, lightweight construction and durability. For civil shipbuilding, such as cargo ships and passenger ships, high-strength stainless steels and aluminium alloys are often used, which are both cost-efficient and resistant to the harsh conditions at sea. The same applies to offshore structures such as offshore wind farms.

Laro NC-Technik offers a wide range of services for this purpose, including consulting, feasibility analyses, simulations, machining and surface finishing.

Laro NC-Technik offers a wide range of services for this purpose, including consulting, feasibility analyses, simulations, machining and surface finishing.

- 100% Made in Germany

- Guaranteed confidentiality & highest safety standards

- Highest precision & reliability

- Special expertise for large thin-walled parts

- Tested and corrosion-resistant milled parts

Laro NC technology: Milling shop for the maritime and offshore industry

EN 9100 certification

Certified CNC service in accordance with the strict requirements of DIN EN 9100:2018 for the aerospace sector.

Certified CNC service in accordance with the strict requirements of DIN EN 9100:2018 for the aerospace sector.

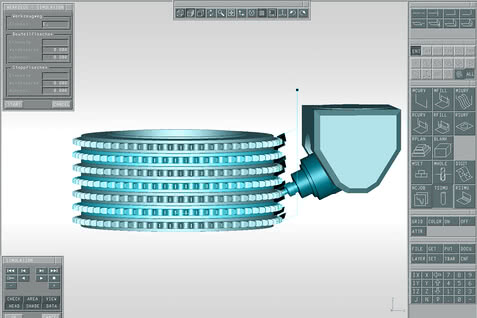

Feasibility analysis

Virtual machines allow the complete simulation of the machining processes before the actual manufacturing stage in order to achieve optimisation and material savings.

Virtual machines allow the complete simulation of the machining processes before the actual manufacturing stage in order to achieve optimisation and material savings.

✔ High-volume machining

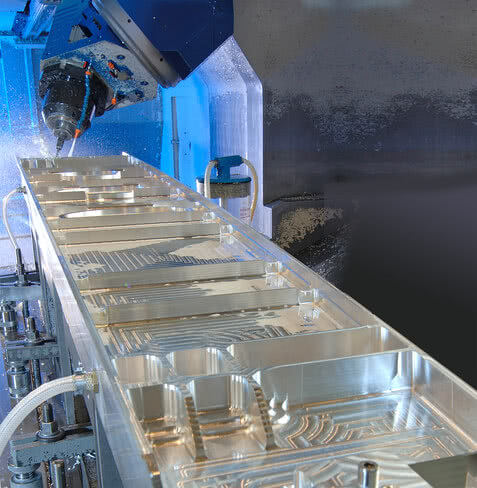

Our measurement sizes enable HPC/HSC milling of large parts with lengths up to 6,000 mm and weights up to 20 tons.

Our measurement sizes enable HPC/HSC milling of large parts with lengths up to 6,000 mm and weights up to 20 tons.

✔ Express milling

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

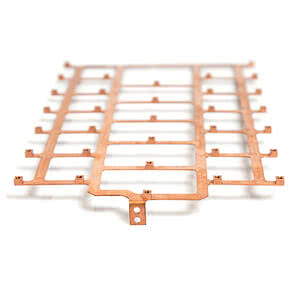

SHIPBUILDING COMPONENTS

for the civil and military fleet

The requirements in shipbuilding are diverse and demanding. At LARO NC-Technik, we understand the challenges that the supplier industry has to overcome when machining shipbuilding components and offer customised solutions. The components required are just as diverse and consist of a wide variety of materials and alloys such as aluminium, stainless steel, titanium, invar, bronze and CFRP.

LARO NC-Technik has many years of experience in the supply of high-precision CNC milled parts for a wide range of industries. Our CNC milling machines and applications are designed to efficiently produce both small batch sizes and variable small series.

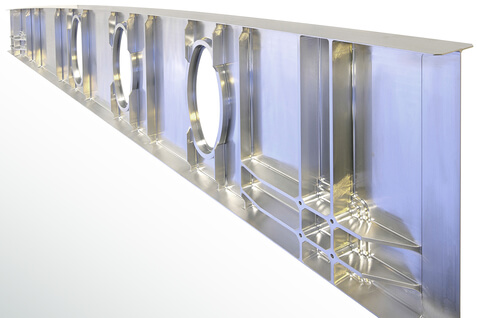

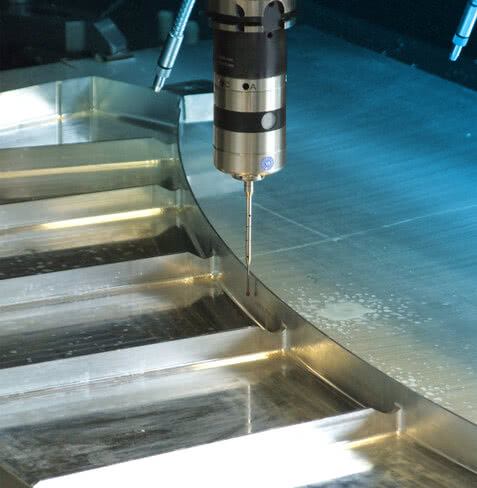

Thanks to High Performance Cutting (HPC) and High Speed Cutting (HSC), we are your reliable partner, especially when it comes to machining large components up to 6 metres in length. Our experienced employees and state-of-the-art technologies enable the precise and efficient machining of complex and large shipbuilding components.

LARO NC-Technik has many years of experience in the supply of high-precision CNC milled parts for a wide range of industries. Our CNC milling machines and applications are designed to efficiently produce both small batch sizes and variable small series.

Thanks to High Performance Cutting (HPC) and High Speed Cutting (HSC), we are your reliable partner, especially when it comes to machining large components up to 6 metres in length. Our experienced employees and state-of-the-art technologies enable the precise and efficient machining of complex and large shipbuilding components.

- Hulls and decks: CNC machining of large-format aluminium and composite panels used for the construction of ship hulls and decks.

- Cabins and interior fittings: precision milled parts for cabins and other interior fittings.

- Ship generator: large-format covers and motor housings, stator elements, milled cooling fins, brackets, holders.

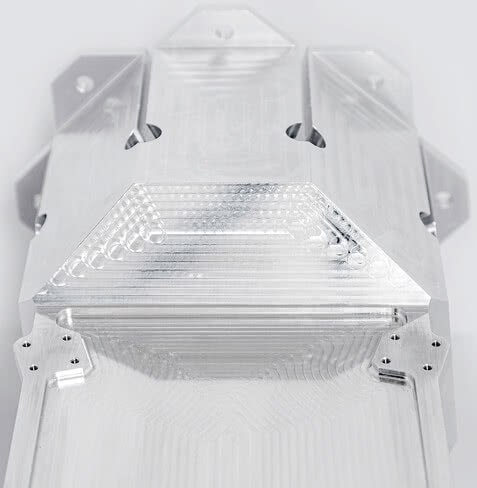

- Prototypes and moulds: Production of prototypes and tools for moulds required in shipbuilding.

PROTOTYPING AND TOOLMAKING

for the maritime industry

LARO NC-Technik GmbH offers comprehensive services in the field of prototype construction and mould construction, which are specially tailored to the needs of shipbuilding, the navy, offshore construction and wind farms . With ISO-certified manufacturing processes such as EN 9100:2018, we guarantee the highest quality and precision in these demanding industries. The development and validation of designs in shipbuilding and marine are integral parts of our process. We ensure that every component meets the stringent requirements of the shipbuilding and marine industries. When producing small series, pilot series and test series , LARO NC-Technik uses strict test criteria to ensure that all milled parts more than fulfil the requirements before they are integrated into the final production process.

Our high-precision milled parts are corrosion-resistant and mechanically resilient to ensure the structural integrity and longevity of offshore installations. In the wind farm sector, we can support offshore wind turbine manufacturers by supplying milled parts that can withstand the harsh environmental conditions at sea.

Wide-ranging expertise and an exceptionally powerful machine park make us the ideal partner for all cases. Convince yourself of the expertise and commitment of our employees.

Make an appointment now for a non-binding consultation!

Our high-precision milled parts are corrosion-resistant and mechanically resilient to ensure the structural integrity and longevity of offshore installations. In the wind farm sector, we can support offshore wind turbine manufacturers by supplying milled parts that can withstand the harsh environmental conditions at sea.

Wide-ranging expertise and an exceptionally powerful machine park make us the ideal partner for all cases. Convince yourself of the expertise and commitment of our employees.

Make an appointment now for a non-binding consultation!

Specialised in tools for innovative carbon fibre composite parts

When it comes to manufacturing high-strength tools from INVAR or titanium alloys for the production of CFRP components, shipbuilding and submarine manufacturers in Germany and Europe can rely on the expertise of Laro NC-Technik as a milling shop. We offer you experienced and highly professional service, from advice on tool design and material selection to the finished tool with the desired surface quality.

- INVAR, a nickel-iron alloy, is characterised by an extremely low coefficient of thermal expansion, which makes it particularly suitable for tools such as punches and dies, where precision and dimensional accuracy are crucial. However, machining INVAR poses particular challenges as it has a high toughness and a tendency to work harden. This requires the use of special cutting tools and optimised machining parameters to ensure precise and efficient production.

- TITANIUM or TITANIUM ALLOYS are known for their high strength and corrosion resistance, making it an ideal material for durable tools. However, titanium is also difficult to machine due to its low thermal conductivity and high chemical reactivity.

Marine shipbuilding and CNC machining for submarines

Naval ship and submarine manufacturers use CNC-machined components in hulls, propulsion systems and structures. These include components such as folding frames, gearbox housings, engine housings or stainless steel covers that can withstand salt water, extreme loads and aggressive environments at sea. Laro NC-Technik GmbH can mill stainless steels and titanium alloys using high-speed cutting (HSC) to produce even complex ship and submarine parts such as propellers and tower superstructures.

Examples of CNC-machined components on military vessels and submersibles include, but are not limited to:

Examples of CNC-machined components on military vessels and submersibles include, but are not limited to:

Tower superstructures / brackets

These serve as structural components that support radar and communications equipment and provide protection for these systems.

Engine blocks / cylinder heads

for the marine generator in ships and submarines to generate propulsion and on-board power.

Heat shields / protective covers

CNC-machined bonnets and covers provide reliable protection against extreme temperatures and mechanical impacts on the ship's generator.

Pump housings / compressors

These are essential for the hydraulic and cooling systems on board and are made from corrosion-resistant materials.

Rudder / Stabilisers

The ship's manoeuvrability and stability are precisely milled to ensure optimum performance.

Materials for seagoing vessels, submarines, special ships

The navy has a variety of ship types designed for different tasks and missions, such as frigates, corvettes, speedboats, submarines, submarine hunters, mine countermeasures vessels, supply ships and various auxiliary vessels. Lightweight construction and corrosion resistance are crucial for the speed, manoeuvrability and operational safety of any type of seagoing vessel. Aluminium alloys are ideal for components such as superstructures and hull structures. Laro NC-Technik has special expertise in the machining of demanding titanium alloys, particularly for titanium submarine parts.

| Metal | Material Designation | Properties |

|---|---|---|

Titanium Alloys | Ti-6Al-4V, Ti-6AL-4V ELI, 6AL-6V-2Sn-Ti | high strength, low weight, corrosion resistance, fatigue resistance at high cycles - used in aerospace, marine, chemical industry, biomedicine |

Aluminium Alloys with Magnesium | EN AW 5754, EN AW 5083 | medium to high strength, weldable - used in shipbuilding, transportation, pressure vessels, bridges and buildings, as AA5024 (AlMgSc) also for aviation applications |

Aluminium Alloys with Magnesium + Silicon | EN AW 6082, EN AW 6060, EN AW 6061 | very easy to weld and extrude - mainly used as extruded profiles |

Aluminium Alloys with Zinc | EN AW 7010, EN AW 7019, EN AW 7020, EN AW 7040, EN AW 7050, EN AW 7074, EN AW 7075 | high to very high strength - used in aircraft construction, aerospace, sports equipment, cell phone and watch casings |

Tool Steel | 1.1xxx, 1.2xxx, 1.3xxx | mainly for the production of active elements of tools, such as rollers, punches, dies, reinforcement rings, bending blades |

Stainless Steel | 1.4xxx | resistant to moisture, alkalis, acids, chloride, air pollutants - Widely used in mechanical engineering, plant construction, apparatus engineering, pumps, sanitary, heating, household, medicine and much more. |

Manganese Steel | 1.3401 | also known as hard manganese steel or hard manganese steel - due to its high wear resistance, it is used in applications with high impact and shock loads |

(Ballistic) Protective Steel | HB477-540, HB530-590, HB580-640, HB630-700 | explosion-resistant, flexible, weldable, maximum resistance to cyclic stress and fatigue - used for armor plating (armor steel) |

Duplex Steel | 1.4462 | high strength and yield strength, very resistant to corrosion and seawater - used in the maritime and offshore industry, chemical industry, food industry, apparatus and tank construction |

We find the right solution for every component. High-speed cutting (HSC milling) enables maritime milled parts to be manufactured particularly quickly. From thin-walled workpieces with low weight to heavy-duty machining: we have solutions for practically every project. We manufacture highly complex components and guarantee you continuous process reliability.

STEALTH TECHNOLOGY IN SHIPBUILDING

The path to a future stealth ship

In shipbuilding, stealth technology, known from military aircraft construction, aims to make it more difficult or impossible to locate ships using radar, sonar, infrared and visual methods. This technology is achieved through special construction methods and materials that minimise the reflection and emission of signals. Radar absorbing materials (RAM) reduce radar reflection and make ships more difficult for enemy radar systems to detect. Glass fibre and carbon fibre composites are lightweight materials that both reduce weight and minimise radar and infrared signatures. Special camouflage coatings minimise the infrared and heat signatures of ships and submarines.

Laro NC-Technik supplies milled components made of titanium and CFRP, as well as tools for GRP/CFRP mould construction made of resistant materials such as Invar and special tool steel.

Laro NC-Technik supplies milled components made of titanium and CFRP, as well as tools for GRP/CFRP mould construction made of resistant materials such as Invar and special tool steel.

CNC contract manufacturing for offshore wind turbines

Offshore wind energy plays a decisive role in sustainable energy generation. The manufacture and maintenance of these systems requires high-precision and robust components that can withstand the extreme conditions at sea.

Milled components are essential for the structure and functionality of offshore wind power. They are used in various areas, including

Milled components are essential for the structure and functionality of offshore wind power. They are used in various areas, including

- Foundations: connecting elements and fastenings that ensure the stability of the turbines.

- Rotor blades: Precisely manufactured components that ensure the assembly, alignment control, efficiency and durability of the rotor blades.

- Nacelle and tower: Structural parts that support the mechanical integrity and safety of the turbine.

- Offshore wind turbine: fasteners, connectors and covers

Range of services offered by Laro NC-Technik for maritime, offshore and future technologies

If you are looking to have large thin-walled components milled, Laro NC-Technik GmbH is the right partner for you. With our modern and powerful CNC machines, machining large parts is no problem. Machining large parts up to 6,000 mm and 20 tonnes is part of our everyday business. You can rely on precise and safe CNC machining of large parts in our air-conditioned halls.

FPT DINO MAX

High Performance Cutting

High Speed Cutting

Working area X = 6000mm, Y = 3500mm, Z = 1500mm

High Performance Cutting

High Speed Cutting

Working area X = 6000mm, Y = 3500mm, Z = 1500mm

Henri-Line Vertamill 229 Zoom

Working area X = 6000mm, Y = 2850mm, Z = 2100mm

Working area X = 6000mm, Y = 2850mm, Z = 2100mm

Bavius UBZ HP 300/200 T3

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

Bavius UBZ NT 300/200

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

Bavius UBZ NT 300/200

Working area X = 4500mm, Y = 2600mm, Z = 1500mm

FPT Dino

Working area X = 2300mm, Y = 1600mm, Z = 900mm

Working area X = 2300mm, Y = 1600mm, Z = 900mm

Surface coating / surface finishing

- Glass bead blasting

- Powder coating

- Painting

- Passivating

- Anodising

- Silver plating

- Nickel plating

- Galvanising

- Chromic acid anodising

- Hard anodising

- Copper plating

- Chrome plating

- Gold plating

EN 9100:2018 certification

As a regularly EN 9100-certified machining company, we are officially qualified to manufacture parts for special applications. We demonstrably pay attention to the exact documentation of our processes and interfaces. All services and products are fully traceable.

Our EN 9100:2018 certification confirms what our customers have long known: Absolute reliability and the highest quality are our standard.

You can find more information about our EN 9100:2018 certification here.

Our EN 9100:2018 certification confirms what our customers have long known: Absolute reliability and the highest quality are our standard.

You can find more information about our EN 9100:2018 certification here.

Feasibility analysis

We use virtual machines to reliably check the feasibility of your designs without the need for materials or machinery. This allows us to identify and analyse any challenges in advance. We then work with you to find the optimum solution and support you in adapting your design if necessary. CNC components for marine vehicles are often complex. Here in particular, it is worth carrying out a feasibility analysis. This ensures that time and money are invested efficiently.

Surface finishing

Surface coatings and finishes provide additional strength, protection and functionality. Glass bead blasting ensures an even, smooth surface. Powder coating provides a robust and protective layer of colour. Painting allows for flexible colour matching and additional protection. Passivation and anodising increase the corrosion resistance of metal parts, while silver plating and nickel plating improve electrical conductivity and protection against wear. Galvanising, chromic acid anodising and hard anodising create particularly robust and resistant surfaces. Copper plating, chrome plating and gold plating offer aesthetic and functional advantages.

Thin-walled parts

We mill thin-walled parts frequently required in lightweight construction with minimal tolerances for maximum precision. Our experience in this area is the guarantee for your weight-optimised and resistant components and structural parts. The lowest possible weight is of great importance in shipping and marine applications, not only for technical but also for economic reasons.

Aluminium and CFRP/GRP

Our employees are your experts in the machining of aluminium and CFRP/GRP. These materials are particularly valued in the navy as they combine lightness with high stability. Carbon parts and titanium components are lightweight and can withstand heavy external loads. As a proven and versatile material, aluminium alloys are also used in maritime projects.

Large-volume machining

Large-volume machining is also part of our broad area of expertise. Very large components are often required for shipbuilding designs in particular. We manufacture CNC components up to 6,000 mm in size and 20 tonnes in weight with the highest precision.

You can find more information about our services in large-volume machining here.

You can find more information about our services in large-volume machining here.

Milling large parts to the perfect finish

Laro NC-Technik has invested in a 5-axis milling machine from FPT with Sinumerik One control. The quantum leap in terms of efficiency, precision and surface quality for machining large parts has been achieved and the course has been set for automated workpiece feeding.

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

CNC-MILLED SHIPBUILDING AND WIND FARM COMPONENTS

Comprehensive customer service right from the start

Laro NC-Technik contributes to the performance and reliability of civil shipbuilding, marine and offshore systems with precisely manufactured components. CNC machined components are an integral part of these modern technologies. By using advanced materials and precise manufacturing techniques, we ensure that our components fulfil your high requirements.

Have we piqued your interest?

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)