Have CNC parts milled: Precision parts Made in Germany

- CNC contract manufacturer for high-precision small parts up to 1,000 mm and 1.4 tonnes

- Have complex shapes and thin-walled small parts milled

- Comprehensive advice and reliability in all process steps

We use state-of-the-art machinery to mill precise CNC parts for your project. Do you need CNC milling at your project? We are your reliable partner!

CNC machining of parts up to 1.000 mm length

CNC machining for the highest demands

When it comes to machining, we offer CNC milling of small parts for your region with certified expertise. Our quality standards in accordance with EN 9100:2018 certification cover all services in our all-round service package. CNC machining every industry and in any batch size - that's what Laro NC-Technik offers. Choose the material that best suits your requirements from a wide range of metals and non-metals.

Thanks to state-of-the-art CNC-controlled milling machines, we can realise any project quickly, reliably and economically. Small CNC production takes place in special air-conditioned workshops to ensure maximum precision. From the initial feasibility analysis to the final inspection, every work step is carried out in-house or via affiliated companies.

For you, this means: CNC contract manufacturing from a single source and a contact partner for all matters.

Thanks to state-of-the-art CNC-controlled milling machines, we can realise any project quickly, reliably and economically. Small CNC production takes place in special air-conditioned workshops to ensure maximum precision. From the initial feasibility analysis to the final inspection, every work step is carried out in-house or via affiliated companies.

For you, this means: CNC contract manufacturing from a single source and a contact partner for all matters.

Overview of services Having parts CNC milled

| CNC Milling Metals | Details |

|---|---|

| CNC milling non-metals | CFRP, GFRP, various plastics |

| Workpiece length | up to 1000 mm |

| Weight | up to 1.4 t |

| Certification | EN 9100:2018 |

Large-scale machining up to 6,000 mm

We are also your perfect milling service for CNC large part machining with a modern machine park that provides workspaces of up to X = 6000mm Y = 3500mm Z = 1500mm. Large parts are part of our daily business in milling, thanks to air-conditioned workshops with the highest possible precision for objects with a surface load of up to 15 tonnes per square metre.

❱ Laro NC-Technik for large-scale machining

❱ Laro NC-Technik for large-scale machining

CNC milling work in aluminium and other materials

Every CNC machining project brings its own challenges. That's why we provide you with customised components instead of mass-produced goods. We also mill metal and plastic prototypes economically for projects in Europe. For CNC precision parts that really get you ahead, we need the following information in particular:

Intended use

Depending on their intended use, your CNC small parts must fulfil certain requirements. For example, should they be particularly resilient? Is a certain elasticity required? How should the components react to temperature changes? These and many other properties can be realised with our modern 5-axis milling machines in CNC machining. We would be happy to advise you personally on the optimum properties of your small CNC parts.

Design data

Our employees manufacture high-quality components based on your design data. From simple to highly complex shapes, (almost) anything is possible thanks to state-of-the-art processes. Our specialists in small CNC production are always available to help you solve or optimise problems.

Material

The choice of the right material has a major influence on the performance of the finished CNC precision parts. Depending on the application, some materials are more and others less suitable. Choose from a wide range of different metals and non-metals to find the right material for you. Are you unsure which material is best suited to your project? Just ask, we will be happy to advise you.

Enquire now without obligation and get advice!

Production Manager

Compact Machines

Markus Meschenmoser

+49 7558 930-502

Send e-mail

VCard downloaden (.vcf)

Compact Machines

Markus Meschenmoser

+49 7558 930-502

Send e-mail

VCard downloaden (.vcf)

Laro NC-Technik 5-axis milling Machine list in small parts machining

Mikron HPM 1000U

Working area

X = 1000mm

Y = 800mm

Z = 600mm

Working area

X = 1000mm

Y = 800mm

Z = 600mm

DMC 64V linear

working space

X = 640mm

Y = 600mm

Z = 500mm

working space

X = 640mm

Y = 600mm

Z = 500mm

Bavius HBZ TR80

working area

X = 850mm

Y = 850mm

Z = 700mm

working area

X = 850mm

Y = 850mm

Z = 700mm

DMU 100T

Working space

X = 1080mm

Y = 710mm

Z = 710mm

Working space

X = 1080mm

Y = 710mm

Z = 710mm

DMU 70eVo

Working space

X = 750mm

Y = 600mm

Z = 520mm

Working space

X = 750mm

Y = 600mm

Z = 520mm

CNC milling: Contract manufacturing with absolute adherence to deadlines

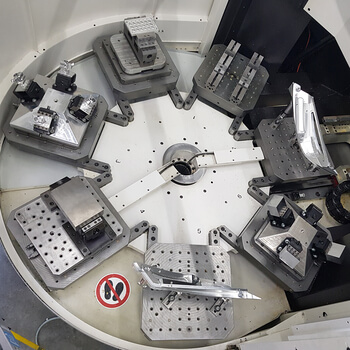

We attach great importance to adherence to delivery dates. Modern machines and short decision-making processes enable us to provide express CNC production of your components and delivery in Europe. Let us know as early as possible when you need your components so that we can plan and deliver accordingly. Thanks to automatic pallet changers, we can have your CNC parts milled 24/7.

CNC parts milling: Why should you commission Laro NC-Technik?

✔ Consultancy

We passionately contribute our wide-ranging repertoire of skills, experience and know-how to your project.

We passionately contribute our wide-ranging repertoire of skills, experience and know-how to your project.

✔ Process chain

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

✔ Quality management

We supplement strict certification requirements with regard to quality, reliability and traceability with our personal ambition and commitment.

We supplement strict certification requirements with regard to quality, reliability and traceability with our personal ambition and commitment.

✔ Express milling

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

CNC 5-axis milling for "one-piece" components

The milling of components is a machining process. In many branches of industry, it is one of the most important types of metalworking. No wonder, because CNC machining has numerous advantages over other methods. Rely on modern milling processes from CNC contract manufacturer Laro NC-Technik to have your small CNC parts milled and avoid the typical problems associated with other moulding processes.

A modern pallet changer (see picture) in the CNC machining department can be loaded with several orders in order to carry out the fully automatic machining of the programmed workpieces around the clock as well as on Sundays and holidays.

A modern pallet changer (see picture) in the CNC machining department can be loaded with several orders in order to carry out the fully automatic machining of the programmed workpieces around the clock as well as on Sundays and holidays.

| Method | Typical Weaknesses | Advantage of CNC Milling |

|---|---|---|

CNC Turning | Limitations in shaping to regular geometry | Freeform surfaces and complex shaping possible |

Welding | Heat distortion/structural change at the weld seam | Comparatively low heat development |

3D Printing | Slow Frequent reworking necessary Metal structure often uneven | Fast express manufacturing usually no post-processing required |

Water Jet Cutting | Partially low cutting speed surface roughness | Fast express manufacturing |

Laser Cutting | Efficiency varies depending on material danger due to high temperature development | Reliable, rapid processing of all specified materials comparatively low heat development |

Metal Injection Molding | High costs limited economic efficiency, especially for large parts | Inexpensive economical for both small and large parts |

How CNC machining works with Laro NC-Technik

Depending on how far along you are in your project planning, we can provide you with the right services. As your system supplier and partner, we support you in all process steps. Would you like to have Laro NC-Technik mill your CNC parts? As a full-service CNC milling company, your project is in reliable hands with us:

Consultancy

We bring our wide-ranging expertise to your order right from the start. Specialists from various fields will work with you to find the optimum solution for your requirements. Our contact partners are available to answer any questions you may have throughout the entire process.

Feasibility study

We save time, material and order costs by offering to check the feasibility of your order in advance. This virtual process simulates the production of your components and visualises potential challenges in advance. If necessary, we then develop an optimised alternative to the original concept.

Machining

Milling small parts of complex shapes in individual and series production is our core competence. Your CNC precision parts are machined using automatic CNC 5-axis milling machines. Our modern and wide-ranging machine park has the right machine for every job.

Finish / quality control

On request, we can then take care of the surface treatment of the finished components directly. Finally, our qualified employees carry out a final inspection. This ensures that all parts correspond exactly to the customer's requirements.

Round-the-clock CNC contract manufacturing and express service thanks to a high degree of automation

We use pallet changing systems to produce both series and individual items fully automatically. Have parts CNC milled around the clock and at weekends? No problem for Laro NC-Technik! We achieve maximum production quantities in the shortest possible time at favourable conditions.

Or we can mill your individual part in an express order practically overnight for punctual delivery.

Or we can mill your individual part in an express order practically overnight for punctual delivery.

Milling work in metal and other materials for your precision parts

You can choose from a total of seven different materials for the production of your CNC precision parts. All materials differ significantly in terms of their properties, making them differently suitable for certain applications.

Steel/stainless steel

Despite their high resistance, hardness and toughness, you can also have steel milled as a metal. Steel components are often used in mechanical engineering and the construction industry, among others, due to their high strength.

Have steel milled

Have steel milled

Aluminium

If you have your components CNC milled from aluminium, you benefit above all from the low weight of this metal. Aluminium is used, for example, in electronics, engine and gearbox construction, aerospace and the construction industry.

Have aluminium milled

Have aluminium milled

Titanium

The special thing about titanium is its high strength and relatively low density. In combination with its high corrosion resistance, it is a popular material for shipbuilding, outdoor equipment, aerospace, racing and construction parts of all kinds.

Invar

Iron-nickel alloys with a very high nickel content are known as Invar or Inconel. Due to its specific properties, it is often used for products that have to guarantee a high degree of length stability, even with temperature fluctuations. Examples include tanks for liquid gas ships, laser housings, RTM tools and astronomical instruments.

CFRP

Carbon fibre reinforced plastics (CFRP) are characterised by high rigidity and low density. They are used, for example, in the manufacture of bicycle frames, aerospace and pressurised gas containers.

GRP

Glass fibre reinforced plastics (GRP), also known as fibreglass, are inexpensive and at the same time of very high quality. Their high elongation at break and elastic energy absorption make them the ideal material for the manufacture of leaf springs, small moulded parts, pipes and industrial doors, for example.

Plastics

Due to their versatility and low cost, plastics are an important part of practically all branches of industry. They are particularly easy to machine and are therefore characterised by low material and production costs.

Have plastic milled

Have plastic milled

TOP AMONG THE CNC COMPANIES:

LARO NC-Technik customer service for your milling work

When it comes to CNC services, we are your worry-free full-service provider for your project. Our range of services goes far beyond machining. We want to support you wherever you are. From the idea to the finished component, we are the right partner for every project and every process stage.

You will be impressed by our customer-orientated company approach: fast response times, adherence to deadlines and openness to new ideas are just a few examples of what makes us stand out as a partner in machining. Our CNC milling services are reasonably priced and reliable.

You will be impressed by our customer-orientated company approach: fast response times, adherence to deadlines and openness to new ideas are just a few examples of what makes us stand out as a partner in machining. Our CNC milling services are reasonably priced and reliable.

Have we piqued your interest?

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)