Have aluminium milled for the highest quality Dresden

- High-precision CNC machining of aluminium in the µ range

- Inexpensive and on-time production of aluminium parts

- Comprehensive aluminium cutting service: advice, analysis, design, milling work, finish

CNC aluminium milling for companies in Dresden

Precise CNC milling work: Aluminium for your needs

Rely on certified expertise for the production of high-quality aluminium milled parts for your company at Dresden. With qualified employees and state-of-the-art CNC machines, we manufacture precise components for all industries. Whether you need complex components, a logo milled or aluminium housings milled: We mould your individual designs economically and quickly. Choose flexibly from any batch size - we can even realise customised products for you at a reasonable price.

If you have aluminium components CNC milled by us, you can be sure that the highest quality standards are met at every stage of the process. This is proven by our EN 9100:2018 certification. You can also benefit from our flexibility. From small CNC aluminium partsto large parts up to 6,000 mm in size and 20 t in weight, everything is possible thanks to our wide range of machinery. Our CNC specialists mill aluminium components in specially air-conditioned workshops to ensure absolute precision.

We offer you a comprehensive aluminium CNC service in an all-round package. As your contact for all matters, we are at your disposal throughout the entire project. From the initial consultation to the final inspection, we provide you with all services from a single source. We ensure that you receive exactly the components you need for your customised project.

If you have aluminium components CNC milled by us, you can be sure that the highest quality standards are met at every stage of the process. This is proven by our EN 9100:2018 certification. You can also benefit from our flexibility. From small CNC aluminium partsto large parts up to 6,000 mm in size and 20 t in weight, everything is possible thanks to our wide range of machinery. Our CNC specialists mill aluminium components in specially air-conditioned workshops to ensure absolute precision.

We offer you a comprehensive aluminium CNC service in an all-round package. As your contact for all matters, we are at your disposal throughout the entire project. From the initial consultation to the final inspection, we provide you with all services from a single source. We ensure that you receive exactly the components you need for your customised project.

Overview of machining services for aluminium and other materials

| CNC Fräsen Stahl | Edelstahl, Manganstahl, Sicherheitsstahl, Werkzeugstahl, ballistischer Sicherheitsstahl, Duplex Stahl, Schmiedeteile aus rostfreien Stählen |

|---|---|

| CNC Fräsen Aluminium | Aluminiumlegierungen EN AW 5083, EN AW 7075, EN AW 6082, EN AW 6060, EN AW 6061, EN AW 2099, EN AW 2196, EN AW 2618, EN AW 5754, EN AW 5083, EN AW 6061, EN AW 6082 |

| CNC Fräsen weitere Materialien | Titan, Invar, CFK, GFK, verschiedene Kunststoffe |

| Werkstücklänge | bis 6000 mm |

| Gewicht | bis 20 t |

| Spezielle Verfahren | High Performance Cutting, High Speed Cutting |

| Zertifizierung | EN 9100:2018 |

Have aluminium CNC milled: We need this information about your project

Would you like to have individual aluminium parts manufactured in almost any size and complexity? Then it is best to send us not only a CAD file, but also additional information about your project. When milling aluminium, the properties of the finished components can be significantly influenced. The more precisely we know the requirements and intended use of your aluminium CNC milled parts, the more comprehensively we can advise and support you with your project.

Intended use

The intended use determines which requirements your aluminium milled parts must meet. Some components may need to be very resilient. Others require high elasticity. Still others must react in a certain way to temperature changes. Properties such as these can be realised in our modern Aluminium Service Center . Our experienced staff will be happy to advise you personally on the efficient CNC machining of aluminium.

Design data

Your design data is the basis for the CNC milling of your aluminium components. From simple to highly complex shapes, (almost) anything is possible thanks to state-of-the-art processes. The specialists from our aluminium CNC service are always available to solve or optimise your problems. Laro NC-Technik uses CATIA for component and mould design. With the help of modern virtualisation methods, the designs of the aluminium milled parts are optimised in advance. This ensures reliable production and makes it possible to test the feasibility of a part and have aluminium parts produced without wasting material.

Adherence to deadlines

Reliability is our top priority. That is why we attach great importance to meeting deadlines. If you have aluminium parts milled by us, you will always receive them within the specified period. Modern machines and short decision-making processes also enable us to provide express CNC production and delivery at short notice for your further aluminium processing Dresden. Let us know as early as possible by when you would like to have your aluminium parts manufactured so that we can plan and deliver accordingly.

Have aluminium milled: Enquire about costs and delivery date without obligation!

Production Manager

Compact Machines

Markus Meschenmoser

+49 7558 930-502

Send e-mail

VCard downloaden (.vcf)

Compact Machines

Markus Meschenmoser

+49 7558 930-502

Send e-mail

VCard downloaden (.vcf)

Aluminium milled parts: Have them manufactured online or at Laro NC-Technik?

Compared to online aluminium CNC suppliers , we not only offer economical and fast production, but also personal advice and customised solutions tailored to your specific requirements. Our many years of experience and our commitment to the highest quality guarantee continuous process reliability. Laro NC-Technik Aluminium CNC Service works flexibly and can produce both small batches and one-offs economically and quickly. Our air-conditioned workshops guarantee absolute precision. Your project is too important to handle aluminium CNC milling online and anonymously. We make your project our project: personalised, reliable and on schedule. This makes us your ideal partner for CNC milled aluminium parts.

✔ Consultancy

We passionately contribute our wide-ranging repertoire of skills, experience and know-how to your project.

We passionately contribute our wide-ranging repertoire of skills, experience and know-how to your project.

✔ Process chain

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

✔ Quality management

We supplement strict certification requirements with regard to quality, reliability and traceability with our personal ambition and commitment.

We supplement strict certification requirements with regard to quality, reliability and traceability with our personal ambition and commitment.

✔ Express milling

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

Having aluminium CNC milled "from one piece"

CNC milling work for aluminium components is a machining process. In many branches of industry, it is one of the most important types of metalworking. No wonder, because milling small aluminium parts has numerous advantages over other methods. When you have your components milled from aluminium at Laro NC-Technik, you avoid the typical problems associated with other shaping processes. Why do we usually mill your component from a single aluminium block?

| Verfahren | Typische Schwächen | Vorteil beim CNC-Fräsen |

|---|---|---|

CNC-Drehen | Einschränkungen in der Formgebung auf Regelgeometrie | Freiformflächen und komplexe Formgebung möglich |

Schweißen | Wärmeverzug/Gefügeveränderung an der Schweißnaht | Vergleichsweise geringe Wärmeentwicklung |

3D-Druck | Langsam häufig Nachbearbeitungen notwendig Metallgefüge oft ungleichmäßig | Schnelle Express-Fertigung i.d.R. keine Nachbearbeitung notwendig |

Wasserstrahlschneiden | Teilweise geringe Schnittgeschwindigkeit Rauheit der Oberfläche | Schnelle Express-Fertigung |

Laserschneiden | Wirkungsgrad variiert je nach Material Gefahr durch hohe Temperaturentwicklung | Zuverlässige, zügige Bearbeitung aller angegebenen Materialien Vergleichsweise geringe Wärmeentwicklung |

Metal Injection Molding | Hohe Kosten Eingeschränkte Wirtschaftlichkeit, insbesondere bei großen Teilen | Preiswert Wirtschaftlich sowohl bei Klein- als auch Großteilen |

CNC milling aluminium: How a project works at Laro NC-Technik

CNC milling aluminium is one of our core competencies. We also offer you all upstream and downstream work steps from a single source. All the services required for this are either available in-house or are carried out by affiliated companies. Laro NC-Technik is your system supplier and partner for all aspects of CNC aluminium cutting. This is how a project works for us:

Consultancy

If you have aluminium components milled by us, our qualified team will bring a wide range of expertise to your order right from the start. On request, we will provide you with detailed, expert advice on your project. We will also be happy to discuss any potential improvements to your design data with you. Specialists from various fields will work with you to find the optimum solution for your requirements. Our contact partners are available to answer your questions throughout the entire process.

Feasibility study

On request, we can carry out a digital feasibility analysis before machining. We check your design data for any challenges that may arise during implementation. This has several advantages for customers who have aluminium parts milled by us: Costs, materials and time required are potentially reduced, as machining can be carried out without any foreseen interruptions. If required, we can develop an optimised alternative to the original design based on the results of our analysis.

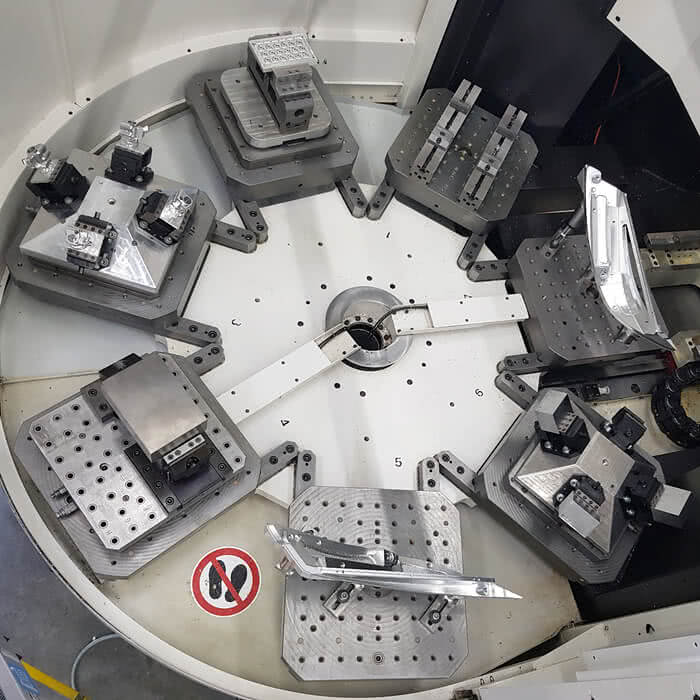

Machining

Based on your design data, we CNC mill aluminium profiles, prototypes and components in sophisticated shapes. Both one-off and series production are possible. We carry out every order precisely according to your wishes using automatic CNC milling machines. Our modern and wide range of machinery is predestined for CNC machining aluminium and many other materials.

Finish / quality control

If you require surface treatment of your finished components, we can carry this out directly on site. Finally, our qualified employees subject all parts to a final inspection. This ensures that they correspond exactly to the customer's requirements and fulfil our high quality standards. Each component is automatically checked in the machine immediately after completion and then visually inspected by an experienced employee.

Round-the-clock contract manufacturing: Aluminium, steel, titanium, Invar, CFRP, GFRP, plastics

By using pallet changing systems, we produce aluminium milled parts - both in series and individual pieces - fully automatically and 24/7. We mill components from aluminium blocks particularly efficiently and economically. This enables us to achieve maximum production quantities in the shortest possible time at favourable conditions. Alternatively, you can have aluminium parts milled as an express order and receive punctual delivery practically overnight, e.g. to Dresden.

Aluminium CNC production: Why is this material so convincing across the board?

In CNC machining, we work with various metals and non-metals. Aluminium is one of the most versatile materials. So it's no wonder that many of our customers have components milled from aluminium. These properties characterise CNC aluminium milled parts for industrial use:

- Cost-effectiveness: Aluminium is a light metal that is relatively easy to machine. CNC milled aluminium parts can therefore be produced more quickly and cost-effectively than other materials. These economic advantages have a positive effect on the price, which ultimately benefits you as the customer.

- Strength: With a density of only around 30% of that of steel, aluminium is a very light metal. Nevertheless, it has an extremely high strength. Despite its low weight, milled aluminium parts are therefore resilient and durable.

- Corrosion protection: Aluminium has its own natural protection against corrosion. The light metal coats itself with an oxide layer in direct contact with oxygen. This renews itself immediately upon penetration. The corrosion resistance can be further enhanced by anodising.

- Temperature resistance: Within a certain temperature range, the properties of aluminium remain constant when the temperature changes. This special feature makes the light metal the first choice for many industrial applications. Its temperature resistance makes aluminium components particularly attractive for precision applications.

- Hygienic surface: Aluminium is characterised by an extremely smooth surface. Dirt particles have no grip here. This makes it particularly easy to clean. Aluminium parts are therefore often used in sterile environments.

- Recyclable: Aluminium can be fully recycled with a fraction of the original energy input. The light metal is fully recyclable without any loss of quality. The use of recycled aluminium makes particular sense when you consider that the extraction of aluminium requires a great deal of energy. Recycling aluminium components reduces your ecological footprint, which is becoming increasingly important in today's world.

Versatile applicability: material advantages of aluminium milled parts

Machining aluminium with CNC milling machines is uncomplicated and economical. In addition, aluminium components are suitable for a wide range of industrial applications due to their numerous positive properties.

Low weight

Due to its lightness, it is extremely popular in the aerospace, traffic and transport industries, for example. Aluminium is also used in mechanical engineering and robotics. Due to its low weight combined with high strength and corrosion resistance, aluminium components are particularly easy to adapt to specific functions.

Non-magnetic

As aluminium is non-magnetic, it is suitable for a wide range of electrotechnical applications. In the sports sector, aluminium is used to improve equipment by replacing heavy components with this light and stable material. The areas of application in the leisure sector are practically unlimited. Here, CNC-milled aluminium components are required for bicycles, ladders, cupboard handles, lamps and caravans, for example.

Non-flammable

Aluminium parts are also frequently used in the construction industry. Aluminium components are increasingly being used in doors, windows, conservatories, railings, shower cubicles and photovoltaic systems. Not only do low weight and high strength play a role here, but also the fact that aluminium is a non-combustible building material.

CNC aluminium milling: Comprehensive customer service right from the start

Place your trust in Laro NC-Technik as an aluminium processing company. Dresden Whether in Germany, Austria, Switzerland or Europe: wherever aluminium milling at the highest level is required, we are your full-service provider with comprehensive aluminium services. Our range of services goes far beyond the machining of aluminium; we want to support you wherever you are in the project. When comparing aluminium machining suppliers Dresden, we are one of the providers of aluminium CNC machining with one of the most powerful machine parks.

From the idea to the finished aluminium milled part, we are the right partner for every aluminium machining project. You will be impressed by our customer-focused company orientation: fast responsiveness, adherence to deadlines and openness to new ideas are just a few examples of what characterises us as a partner in machining. Our CNC milling services are inexpensive and reliable.

From the idea to the finished aluminium milled part, we are the right partner for every aluminium machining project. You will be impressed by our customer-focused company orientation: fast responsiveness, adherence to deadlines and openness to new ideas are just a few examples of what characterises us as a partner in machining. Our CNC milling services are inexpensive and reliable.

Haben wir Ihr Interesse geweckt?

Vereinbaren Sie jetzt einen Termin für ein unverbindliches Beratungsgespräch!

Vertrieb

Tobias Kreft

+49 7558 930-514

E-Mail senden

VCard downloaden (.vcf)

Vereinbaren Sie jetzt einen Termin für ein unverbindliches Beratungsgespräch!

Vertrieb

Tobias Kreft

+49 7558 930-514

E-Mail senden

VCard downloaden (.vcf)

Wer in Dresden individuelle Bauteile benötigt, setzt auf Zerspanungslösungen von Laro NC. Mit unseren Leistungen im Bereich Have aluminium milled bieten wir die passende Lösung für jeden Bedarf. So ist Laro NC in Dresden längst als Lieferant hochwertiger und passgenauer Bauteile bekannt. Dresden, die Landeshauptstadt Sachsens, ist mit 560.000 Einwohnern nach Leipzig die zweitgrößte Kommune im Land. Hier liegen bedeutende Bildungs- und Kultureinrichtungen des Bundeslandes, darunter verschiedene renommierte Universitäten und Hochschulen. Auch wirtschaftlich kommt Dresden eine bedeutende Rolle zu. Als eine der ökonomisch dynamischsten Regionen Deutschlands spielen in Dresden Innovationen und Spitzentechnologien eine herausragende Rolle. In diesem dynamischen Umfeld unterstützen wir unsere Kunden durch hochpräzise Bauteile, insbesondere im Bereich Have aluminium milled.

Große wirtschaftliche Bedeutung haben in Dresden unter anderem Informationstechnik, Nanoelektronik, Pharmazie, Kosmetik und Maschinenbau. Auch als Verkehrsknotenpunkt kommt der Stadt eine wichtige Rolle zu. Dresden ist international für seine zahlreichen historischen Bauwerke bekannt. Dazu zählen beispielsweise der barocke Zwinger, verschiedene bedeutende Museen und berühmte Klangkörper. Großunternehmen, Mittelständler und Familienbetriebe in Dresden kennen bereits seit langem die individuellen Zerspanungslösungen von Laro NC. Mit unseren Leistungen rund um Have aluminium milled unterstützen wir Unternehmen bei der Realisierung nachhaltiger Wettbewerbsvorteile. Kunden in Dresden schätzen dabei insbesondere die hohe Flexibilität sowie den zuvorkommenden Kundenservice.

Große wirtschaftliche Bedeutung haben in Dresden unter anderem Informationstechnik, Nanoelektronik, Pharmazie, Kosmetik und Maschinenbau. Auch als Verkehrsknotenpunkt kommt der Stadt eine wichtige Rolle zu. Dresden ist international für seine zahlreichen historischen Bauwerke bekannt. Dazu zählen beispielsweise der barocke Zwinger, verschiedene bedeutende Museen und berühmte Klangkörper. Großunternehmen, Mittelständler und Familienbetriebe in Dresden kennen bereits seit langem die individuellen Zerspanungslösungen von Laro NC. Mit unseren Leistungen rund um Have aluminium milled unterstützen wir Unternehmen bei der Realisierung nachhaltiger Wettbewerbsvorteile. Kunden in Dresden schätzen dabei insbesondere die hohe Flexibilität sowie den zuvorkommenden Kundenservice.

Have aluminium milled 01454 Radeberg | Have aluminium milled 09599 Freiberg | Have aluminium milled 02625 Bautzen | Have aluminium milled 04758 Oschatz | Have aluminium milled 03238 Finsterwalde | Have aluminium milled 02708 Löbau | Have aluminium milled 09496 Marienberg | Have aluminium milled 09111 Chemnitz | Have aluminium milled 02763 Zittau