Housings and milled parts for semiconductor production

Semiconductor fabs and semiconductor foundries form the technological backbone of our digital world: the production facilities for microchips, CPUs, etc. Without them, smartphones, computers and everything that contains electronic components - i.e. practically all modern technical devices, including cars - would simply be unthinkable.

Laro NC-Technik is your reliable partner for CNC-milled housings and machine parts.

Laro NC-Technik is your reliable partner for CNC-milled housings and machine parts.

- High-quality aluminium housings for extremely precise manufacturing processes

- Customised components for vacuum chambers and cleanrooms

- Expert advice for all work steps

Aluminium housings for high-precision applications

✔ Consultancy

We passionately contribute our wide-ranging repertoire of skills, experience and know-how to your project.

We passionately contribute our wide-ranging repertoire of skills, experience and know-how to your project.

✔ Process chain

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

✔ Quality management

We supplement strict certification requirements with regard to quality, reliability and traceability with our personal ambition and commitment.

We supplement strict certification requirements with regard to quality, reliability and traceability with our personal ambition and commitment.

✔ Express milling

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

SEMICONDUCTOR FAB CONSTRUCTION

Micro-precision for the chip fab and chip foundry

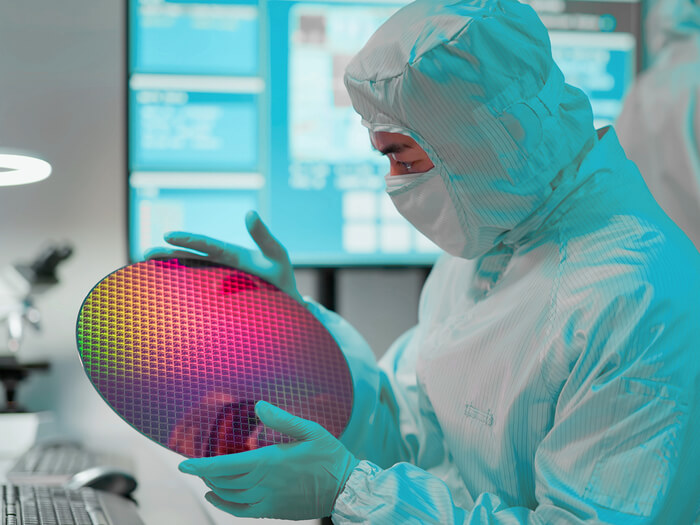

Chip fabs are highly specialised semiconductor factories in which, for example, the leading chip manufacturers produce their semiconductor chips themselves. In contrast, chip foundries work as subcontractors for the so-called fabless industry. In principle, these chip manufacturers do not operate their own chip production, but concentrate on the design and marketing of the microchips they have developed themselves. What semiconductor fabs and semiconductor foundries have in common is that they work with the highest precision in order to process wafer chips under controlled conditions.

The chip production process requires high-precision milled housings and holders for photolithography and laser processing. Laro NC-Technik specialises in the CNC milling of aluminium housings for these demanding precision applications. Our milled components are used in extremely clean production facilities - so-called cleanrooms - where the air is up to 10,000 times cleaner than in an operating theatre. This is because even a single dust particle could impair the function of a microchip and render it unusable for the CPU and circuits.

The chip production process requires high-precision milled housings and holders for photolithography and laser processing. Laro NC-Technik specialises in the CNC milling of aluminium housings for these demanding precision applications. Our milled components are used in extremely clean production facilities - so-called cleanrooms - where the air is up to 10,000 times cleaner than in an operating theatre. This is because even a single dust particle could impair the function of a microchip and render it unusable for the CPU and circuits.

Enquire now without obligation and get advice!

VACUUM CHAMBER FOR CHIP WAFERSMilling high-density aluminium housings from a block

Vacuum chambers are crucial in the semiconductor production process. They provide a controlled, low-pressure environment that is necessary for various production steps. Creating the required air vacuum or a special gas environment requires an absolutely tight housing: weld seams and connections between housing elements would represent potential weak points. Laro NC-Technik therefore mills the basic structure of these housings from large aluminium blocks, often measuring 1 metre or more, in one piece.

Here are some of the main applications and benefits of vacuum chambers in wafer semiconductor processing:

Here are some of the main applications and benefits of vacuum chambers in wafer semiconductor processing:

Contamination control

Vacuum chambers in the cleanroom allow microchips to be manufactured in virtually particle-free environments. This is crucial, as even the smallest impurities can affect the function of the chips. By removing air and other gases, an extremely clean environment is created in wafer chip production, which increases the quality and reliability of the chips.

Plasma / surface treatments

Plasma and surface treatments can be carried out in vacuum chambers to improve the material properties of the wafer semiconductors. These treatments include the cleaning, activation and etching of surfaces, which improves the adhesion of coatings and the electrical performance of the chips.

Deposition processes

Vacuum chambers are used for various deposition processes in which thin layers of materials are deposited on the wafer chips and removed by etching processes in a very fine process. These processes are crucial for the production of semiconductor layers and metallic conductive paths that enable the functionality of the chips.

Doping

The doping of the semiconductor wafer, in which foreign atoms are introduced into the crystal structure, often takes place in vacuum chambers. This enables precise control over the doping processes and improves the electrical performance of the chips.

Thermal processes

Vacuum chambers are also used for thermal processes such as annealing, where the wafers are heated to improve the crystal structure and heal defects. These processes are critical to the performance and reliability of the chips.

Increased precision

The controlled environment in vacuum chambers enables greater precision in various production steps. This leads to better quality and lower reject rates, which increases efficiency in the semiconductor fab process.

HAVING ALUMINIUM HOUSINGS MILLED Precision in the semiconductor fab

Precision is a decisive factor in semiconductor production. Technologies such as photolithography, laser processes and etching processes enable the creation of structures in the nanometre range. Laro NC technology offers high quality CNC machining and cutting, which are essential for the production of precise housings and holders for lasers and wafers in the special clean room environment.

Fab or foundry chip manufacturing benefits from our expertise, highly motivated employees and exceptional machinery in our air-conditioned production halls. We guarantee absolute dimensional accuracy of the milled parts produced.

Fab or foundry chip manufacturing benefits from our expertise, highly motivated employees and exceptional machinery in our air-conditioned production halls. We guarantee absolute dimensional accuracy of the milled parts produced.

Milling large parts to the perfect finish

Laro NC-Technik has invested in a 5-axis milling machine from FPT with Sinumerik One control. The quantum leap in terms of efficiency, precision and surface quality for machining large parts has been achieved and the course has been set for automated workpiece feeding.

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

📰 Read the press article in the trade journal NC-Fertigung here!

📷 Start interactive 360° tour of the machine

Machine and equipment: The FPT Dinomax has Siemens linear motors, a traverse path of 6,000 x 3,500 x 1,500 mm and can machine large parts at up to 22,000 revolutions per minute.

Automation and precision: The machine enables fully automatic, high-precision machining of aluminium and steel. It can change tools weighing up to 35 kg and process workpieces with a surface load of up to 15 tonnes per square metre.

Control system and software: The Sinumerik One control system offers comprehensive software packages and enables seamless integration into the existing infrastructure.

Efficiency and flexibility: The machine can change the milling spindle fully automatically within three minutes, it can switch from HPC High Performance Cutting to HSC High Speed Cutting and offers high repeat accuracy in the µ range.

Automation: Laro NC-Technik is planning palletising systems to further increase the efficiency of CNC machining of large parts.

ALUMINIUM HOUSING MANUFACTURER

for technological advances in the chip production process

Technological progress, for example with extreme ultraviolet (EUV) lithography, makes it possible to manufacture chips with ever smaller structures of less than 7 nanometres. These processes are essential for the production of high-performance processors and are driving innovation in areas such as artificial intelligence, 5G networks and electromobility. Laro NC-Technik supports semiconductor fab equipment manufacturers in these advances by producing high-precision housings and milled parts for semiconductor production equipment.

SEMICONDUCTOR WAFER AND CHIP PRODUCTION

Housings and holders from Laro NC-Technik

Housings and fixtures in semiconductor production equipment play a literally "supporting" role in the protection and error-free manufacture of semiconductors. Laro NC-Technik manufactures individual and special milled parts up to 6,000 mm in length and 20 tonnes in weight from various materials such as aluminium, steel, Invar, titanium and various plastics. Our high quality standards qualify us for CNC contract manufacturing for semiconductor fab equipment. Through intensive personal consultation and continuous process reliability, we ensure that our aluminium housings and milled parts meet the highest requirements of the semiconductor industry.

Lithography: Semiconductor production in one-piece housings

Our aluminium housings are also very important in the field of lithography semiconductor development. In photolithography, semiconductors are produced using an exposure process. In order for semiconductor lithography production to run safely and precisely, the process must be reliably protected from external influences, which is guaranteed by our high-quality enclosures. In the highly competitive semiconductor industry, our customers benefit from customised solutions, short lead times and fair prices.

Processing semiconductor wafers in a safe environment

Wafers for semiconductors require the highest precision in industrial processing. Differences of just a few nanometres can have an impact on the quality of end products. Our aluminium housings also offer the necessary protection against undesirable environmental influences for semiconductor wafers. This ensures consistent quality in your production and avoids unnecessary rejects.

Regardless of your industry, we will find the right solution to support you in sensitive manufacturing processes such as wafer production. We implement your construction plans precisely and deliver your parts on time.

Regardless of your industry, we will find the right solution to support you in sensitive manufacturing processes such as wafer production. We implement your construction plans precisely and deliver your parts on time.

ALUMINIUM HOUSINGS

What are the advantages of aluminium as a material?

We mill high-quality CNC components from a wide variety of metals and non-metals. When it comes to housings for precision applications, however, we rely on aluminium. The advantages of having aluminium housings milled include the following:

Economic efficiency

Aluminium is a light metal that is relatively easy to machine. Aluminium components can therefore be produced more quickly and cost-effectively than other materials. These economic advantages have a positive effect on the price, which ultimately benefits you as the customer.

Strength

With a density of only around 30% of that of steel, aluminium is a very light metal. Nevertheless, it is extremely strong. Components and processes inside a solid aluminium housing are therefore very effectively protected against external influences.

Corrosion protection

Aluminium has its own natural protection against corrosion. The light metal coats itself with an oxide layer in direct contact with oxygen. This renews itself immediately upon penetration. The corrosion resistance can be further enhanced by anodising.

Temperature resistance

Within a certain temperature range, the properties of aluminium remain constant when the temperature changes. This special feature makes the light metal the first choice for many industrial applications. Its temperature resistance makes aluminium housing profiles particularly attractive for precision applications.

Hygienic surface

Aluminium is characterised by an extremely smooth surface. Dirt particles have no grip here. This makes it particularly easy to clean. Aluminium enclosures are therefore often used in sterile environments.

Sustainability

Aluminium can be completely recycled with a fraction of the original energy input. The light metal can be fully recycled without any loss of quality. This makes particular sense when you consider that the extraction of aluminium requires a great deal of energy. Recycling aluminium components reduces your ecological footprint, which is becoming increasingly important in today's world.

HAVE ALUMINIUM MILLEDWhat do high-quality enclosures for precision applications cost?

No two customer projects are the same. We specialise in finding individual solutions for individual problems. Our qualified employees look forward to your challenge. We also find the right answer to unusual or extravagant customer requests. Let us know exactly what you need and you will receive your customised quotation immediately.

| CNC Milling Metals | Details |

|---|---|

| CNC milling non-metals | CFRP, GFRP, various plastics |

| Workpiece length | up to 1000 mm |

| Weight | up to 1.4 t |

| Certification | EN 9100:2018 |

CNC milled parts - References

CNC HOUSING PRODUCTION AT LARO NC-TECHNIK

Comprehensive customer service right from the start

The semiconductor fab process is a highly complex and precise process that requires state-of-the-art technologies and the highest standards. Semiconductor fabs require a production facility with extremely precise equipment to manufacture microprocessors, memory modules and other integrated circuits. Laro NC-Technik makes a decisive contribution to the quality and efficiency of semiconductor production at chip production companies with its high-precision milled housings and fixtures.

Have we piqued your interest?

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)

Make an appointment now for a non-binding consultation!

Sales

Tobias Kreft

+49 7558 930-514

Send e-mail

VCard downloaden (.vcf)