Have plastic CNC milled to the highest quality Iserlohn

- CNC milling: plastics and fibre composites

- Cost-effective production of simple and complex moulds

- Personalised advice with a dedicated contact person

Our services: CNC milling of plastic for projects in the room Iserlohn

CNC milled plastic parts: what sets us apart

We are your reliable partner for the CNC machining of plastic. We can supply you with plastic milled parts of the highest production quality and in almost any size. We are at your side for your customised projects across all industries. Our flexible manufacturing system enables the economical production of any batch size, from prototype to series production.

We have state-of-the-art milling machines and a team of qualified employees for the precise CNC machining of plastic. We manufacture your CNC milled plastic parts in special air-conditioned workshops. This enables us to guarantee maximum mould accuracy so that you always receive exactly the components you need. We are your all-round partner for your company at Iserlohn. In plastic CNC production, we take care of all the necessary work steps, from feasibility analyses to quality control. Our comprehensive CNC service is rounded off by detailed advice from a dedicated contact person.

We have state-of-the-art milling machines and a team of qualified employees for the precise CNC machining of plastic. We manufacture your CNC milled plastic parts in special air-conditioned workshops. This enables us to guarantee maximum mould accuracy so that you always receive exactly the components you need. We are your all-round partner for your company at Iserlohn. In plastic CNC production, we take care of all the necessary work steps, from feasibility analyses to quality control. Our comprehensive CNC service is rounded off by detailed advice from a dedicated contact person.

Milling plastic: Our qualifications

Thanks to our many years of experience and wide-ranging expertise, we meet the highest standards in plastics processing. The following points, among others, qualify us for the production of complex and high-quality plastic components:

- Thin-walled parts: We manufacture thin-walled components with minimal tolerances for maximum accuracy. Benefit from our experience in this demanding field when manufacturing weight-optimised and resistant plastic components.

- Machining in any size: We can supply you with high-precision small parts and large components up to 6,000 mm in size and 20 tonnes in weight that meet your exact specifications.

- EN 9100:2018 certification: This certification confirms what our customers have long known: Absolute reliability and the highest quality are our standard. The certification relates to the production of aerospace parts, but we implement these high standards in all areas of production.

A compact overview of our services

| CNC Fräsen Stahl | Edelstahl, Manganstahl, Sicherheitsstahl, Werkzeugstahl, ballistischer Sicherheitsstahl, Duplex Stahl, Schmiedeteile aus rostfreien Stählen |

|---|---|

| CNC Fräsen Aluminium | Aluminiumlegierungen EN AW 5083, EN AW 7075, EN AW 6082, EN AW 6060, EN AW 6061, EN AW 2099, EN AW 2196, EN AW 2618, EN AW 5754, EN AW 5083, EN AW 6061, EN AW 6082 |

| CNC Fräsen weitere Materialien | Titan, Invar, CFK, GFK, verschiedene Kunststoffe |

| Werkstücklänge | bis 6000 mm |

| Gewicht | bis 20 t |

| Spezielle Verfahren | High Performance Cutting, High Speed Cutting |

| Zertifizierung | EN 9100:2018 |

Plastic machining: How we get your CNC milled plastic parts into shape

Have customised plastic components milled for your project at Iserlohn: Our aim is to ensure that the result fully meets your expectations. Communication and cooperation are essential, which is why we provide you with a contact person for all matters. The more information you provide us with about your project, the more comprehensively we can support you in your endeavours. This information is particularly relevant for us:

Intended use

Depending on their intended use, your CNC plastic components must fulfil certain requirements. For example, should they be particularly resilient? Is a certain degree of elasticity required? How should the parts react to temperature changes? These and many other properties can be realised with our modern CNC milling machines for plastics processing. We would be happy to advise you personally on the optimum properties of your CNC plastic components.

Design data

Our employees manufacture high-quality plastic milled parts based on your design data. From simple to highly complex moulds, (almost) anything is possible thanks to state-of-the-art processes. Our specialists in plastic CNC production are always available to help you solve or optimise problems.

Material

Plastics are particularly easy to machine and are therefore characterised by low material and production costs. However, not all plastics are the same. It can make a big difference to your components whether we mill them from POM plastic or ABS plastic, for example. Depending on the application, some materials are more and others less suitable. Are you unsure which material is best suited to your project Iserlohn? Just ask us, we will be happy to advise you.

Deadline

We attach great importance to adherence to delivery dates. You can rely on us to meet fixed delivery dates. Modern machines and short decision-making processes also enable us to provide express CNC production of your components at short notice. Let us know as early as possible when you need your components so that we can plan and deliver accordingly.

Enquire now without obligation and get advice!

Production Manager

Compact Machines

Markus Meschenmoser

+49 7558 930-502

Send e-mail

VCard downloaden (.vcf)

Compact Machines

Markus Meschenmoser

+49 7558 930-502

Send e-mail

VCard downloaden (.vcf)

Why should you have your plastic components milled by Laro NC-Technik?

✔ Consultancy

We passionately contribute our wide-ranging repertoire of skills, experience and know-how to your project.

We passionately contribute our wide-ranging repertoire of skills, experience and know-how to your project.

✔ Process chain

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

✔ Quality management

We supplement strict certification requirements with regard to quality, reliability and traceability with our personal ambition and commitment.

We supplement strict certification requirements with regard to quality, reliability and traceability with our personal ambition and commitment.

✔ Express milling

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

CNC milled plastic parts: What are the advantages of milling "from a single piece"?

The milling of components is a machining process. In many branches of industry, it is one of the most important types of plastics processing. No wonder, because CNC milling has numerous advantages over other methods. Rely on modern milling processes from Laro NC-Technik and avoid the typical problems associated with other moulding processes.

| Verfahren | Typische Schwächen | Vorteil beim CNC-Fräsen |

|---|---|---|

CNC-Drehen | Einschränkungen in der Formgebung auf Regelgeometrie | Freiformflächen und komplexe Formgebung möglich |

Schweißen | Wärmeverzug/Gefügeveränderung an der Schweißnaht | Vergleichsweise geringe Wärmeentwicklung |

3D-Druck | Langsam häufig Nachbearbeitungen notwendig Metallgefüge oft ungleichmäßig | Schnelle Express-Fertigung i.d.R. keine Nachbearbeitung notwendig |

Wasserstrahlschneiden | Teilweise geringe Schnittgeschwindigkeit Rauheit der Oberfläche | Schnelle Express-Fertigung |

Laserschneiden | Wirkungsgrad variiert je nach Material Gefahr durch hohe Temperaturentwicklung | Zuverlässige, zügige Bearbeitung aller angegebenen Materialien Vergleichsweise geringe Wärmeentwicklung |

Metal Injection Molding | Hohe Kosten Eingeschränkte Wirtschaftlichkeit, insbesondere bei großen Teilen | Preiswert Wirtschaftlich sowohl bei Klein- als auch Großteilen |

Milling plastic: How does a project with Laro NC technology work?

If you have plastic components CNC milled by us, we are always available to provide you with the right services. As your system supplier and partner, we support you in all process steps involved in the CNC milling of plastic parts. This is how a project works for us:

Consultancy

Right from the start, we bring our wide-ranging expertise to your order. Is there potential for improvement in the design data? Which plastic is suitable for milling? Specialists from various departments will work with you to find the optimum solution for your requirements. Our contact partners are available to answer your questions throughout the entire process.

Feasibility study

We save time, material and order costs by offering to check the feasibility of your order in advance. This virtual process simulates the production of your components and visualises potential challenges in advance. If necessary, we then develop an optimised alternative to the original concept.

Machining

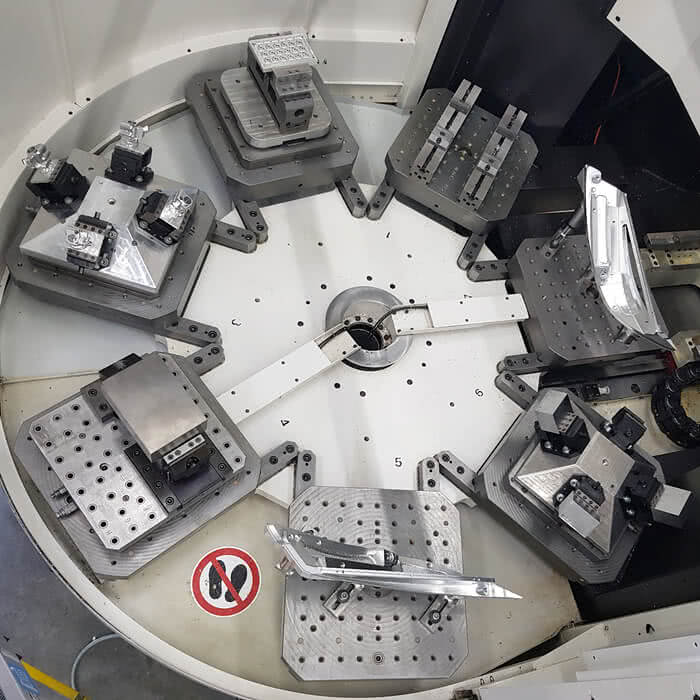

CNC plastic milling of sophisticated moulds in individual and series production is our core competence. We CNC mill your plastic parts using automatic CNC milling machines. Our modern and wide-ranging machine park has the right machine for every job.

Finish / quality control

On request, we can then take care of the surface treatment of the finished components directly. Finally, our qualified employees carry out a final inspection. This ensures that all parts correspond exactly to the customer's requirements.

Round-the-clock production thanks to a high degree of automation

Whether you want to have filigree prototypes or simple plastic panels manufactured: By using pallet changing systems, we produce both series and individual items fully automatically. This enables us to achieve maximum production quantities in the shortest possible time at favourable conditions.

Alternatively, we can mill your individual item practically overnight as an express order for punctual delivery to Iserlohn.

Alternatively, we can mill your individual item practically overnight as an express order for punctual delivery to Iserlohn.

Universal material: In which industrial sectors are milled plastic parts used?

Plastic components and CNC cut parts have numerous advantageous properties, including low material costs, low production costs, free mouldability and high stability. It is therefore no wonder that they are used practically everywhere in industry. Typical areas of application include the following.

Automotive industry

CNC-milled plastic components are indispensable in the manufacture of motor vehicles of all kinds. They not only play a key role from a technical point of view. As high-quality visible parts, they also have a significant influence on the appearance and perceived value of cars. With our plastic milling service, we offer you an uncomplicated and reliable way to have the required plastic CNC components for the automotive sector manufactured quickly and reliably.

Housing

Whether coffee machine, hammer drill, measuring instrument or computer: the right housing makes electronic devices more user-friendly, durable and visually appealing. CNC-milled plastic components are stable and lightweight. In addition, the most sophisticated designs can be realised cost-effectively. When you have plastic housings CNC-milled by us, you benefit from favourable conditions, certified expertise and the highest level of adherence to deadlines.

medicine

It is not without reason that plastics are among the most widely used materials in medical technology. Components milled from plastic are water-resistant, do not absorb odours and are economical to manufacture. Naturally, high demands are placed on these components. We carry out CNC plastic milling on state-of-the-art machines in specially cooled workshops. This enables us to guarantee the highest quality and dimensional accuracy, even for medical components.

Sports boats

Materials for sports boats must meet high standards. These include high strength, the lowest possible weight and a visually and haptically sophisticated design. Parts of pleasure craft are therefore often made from components that manufacturers have milled from plastic. In order to meet the high demands of recreational boat construction, we offer you high-precision components from our certified plastic CNC machining.

Art and creative realisations

Plastic components are also ideal for creative applications. They are much more flexible in their design than metal parts and are often cheaper to manufacture. For artists who are wondering how to mould their ideas, we offer the rapid and economical production of precise CNC components from a batch size of just one piece.

Customised applications

Our qualified team welcomes every new challenge. You are also welcome to approach us with extravagant and unusual orders. We have the experience, expertise and equipment to find the right solution for your individual project.

Plastic milling CNC: Holistic customer service right from the start

When it comes to CNC service, we are your full-service provider for Iserlohn with the all-round carefree package. Our range of services goes far beyond machining - we want to support you wherever you are.

From the initial idea to the finished component, we are the right partner for every project. You will be impressed by our customer-orientated company approach: fast response times, adherence to deadlines and openness to new ideas are just a few examples of what makes us stand out as a partner in machining. Our CNC milling services are affordable and reliable.

From the initial idea to the finished component, we are the right partner for every project. You will be impressed by our customer-orientated company approach: fast response times, adherence to deadlines and openness to new ideas are just a few examples of what makes us stand out as a partner in machining. Our CNC milling services are affordable and reliable.

Haben wir Ihr Interesse geweckt?

Vereinbaren Sie jetzt einen Termin für ein unverbindliches Beratungsgespräch!

Vertrieb

Tobias Kreft

+49 7558 930-514

E-Mail senden

VCard downloaden (.vcf)

Vereinbaren Sie jetzt einen Termin für ein unverbindliches Beratungsgespräch!

Vertrieb

Tobias Kreft

+49 7558 930-514

E-Mail senden

VCard downloaden (.vcf)

Iserlohn, eine Stadt im Herzen des märkischen Kreises in Deutschland, ist bekannt für ihre starke industrielle Prägung. Die Region hat sich besonders in den Bereichen Maschinenbau, Fahrzeugbau sowie Luft- und Raumfahrt einen Namen gemacht und beherbergt zahlreiche Unternehmen, die in diesen innovativen Branchen tätig sind. Die örtliche Industrie profitiert von der langjährigen Tradition des Ingenieurwesens sowie der Verfügbarkeit ausgebildeter Fachkräfte.Durch die Nähe zu wichtigen Verkehrsanbindungen ist Iserlohn geografisch optimal positioniert, um nicht nur lokale, sondern auch überregionale Märkte zu bedienen. Die verkehrsgünstige Lage ermöglicht Logistiklösungen, die für die schnelle und effiziente Produktion unabdingbar sind. Daher ist die Stadt ein idealer Standort für Unternehmen, die Wert auf Prozesssicherheit und zeitgerechte Lieferung legen.In diesem industriellen Umfeld bietet die Laro NC-Technik GmbH als zuverlässiger und innovativer Partner in der CNC-Bearbeitung entscheidende Vorteile. Mit einem zertifizierten Qualitätsmanagement nach anerkannten Standards gewährleistet Laro NC-Technik eine hohe Prozesssicherheit, die für die anspruchsvollen Branchen der Region von großer Bedeutung ist. Die Flexibilität in der CNC-Fertigung ermöglicht es, maßgeschneiderte Werkstücke, Werkzeuge, Prototypen und Cubing bis zu beachtlichen Längen herzustellen, wobei eine Vielzahl von Materialien bearbeitet werden kann.Laro NC-Technik versteht die besonderen Anforderungen, die an Unternehmen im Maschinen- und Fahrzeugbau sowie in der Luft- und Raumfahrt gestellt werden. Die Zusammenarbeit mit diesem Unternehmen bedeutet, einen persönlichen Ansprechpartner an der Seite zu haben, der von der ersten Beratung bis hin zur CNC-Simulation und der finalen Herstellung des Frästeils einen umfassenden Full-Service bietet. Dies trägt dazu bei, dass Projekte effizient und zielgerichtet umgesetzt werden.Die vollständige Fertigung in Deutschland bietet zusätzliche Vorteile, wie kurze Reaktionszeiten und eine hohe Verfügbarkeit von Ressourcen, was gerade in den dynamischen Branchen, die in Iserlohn ansässig sind, unerlässlich ist. Die Laro NC-Technik GmbH hat sich aufgrund dieser Eigenschaften als ein wertvoller Partner für Unternehmen etabliert, die auf Qualität, Flexibilität und Innovation setzen.

Have plastic milled 58095 Hagen | Have plastic milled 58507 Lüdenscheid | Have plastic milled 59759 Arnsberg | Have plastic milled 44135 Dortmund | Have plastic milled 58452 Witten | Have plastic milled 59065 Hamm | Have plastic milled 44787 Bochum | Have plastic milled 42275 Wuppertal | Have plastic milled 42853 Remscheid | Have plastic milled 45657 Recklinghausen