Milling precision parts from stainless steel and steel for Taufkirchen and Europe

- High-precision CNC steel and metal machining in the µ range

- Have high-strength steel milled

- Have hardened steel milled

- Comprehensive advice and full service from design to finish

Contract manufacturing CNC steel milling Taufkirchen

Have steel CNC milled in certified quality and almost any size

If you want to have high-quality milled parts made from steel, Laro NC-Technik is your first port of call. With qualified personnel and state-of-the-art machinery, we can shape your steel CNC components economically and reliably. We can provide you with precise components for your individual requirements across all industries at Taufkirchen. Optimised production processes enable the cost-effective machining of steel in any batch size - from individual items to series production.

Our EN 9100:2018 certification confirms the high quality standards that you can expect from us in CNC contract steel manufacturing. We carry out the CNC machining of your steel parts in special air-conditioned workshops. In this way, temperature-related deformations are reliably excluded and maximum precision is guaranteed. Do you need special steel components that are particularly small, large or thin-walled, for example? No problem: our experienced steel milling team is happy to take on any challenge and will find the right solution for your project.

We do not simply see ourselves as a service provider who can mill steel for you. Rather, we want to support you as a partner in your project. From the initial consultation to the final inspection, we therefore offer all services from a single source. We provide you with a dedicated contact person for all matters, ensuring that you receive exactly the components you need.

Our EN 9100:2018 certification confirms the high quality standards that you can expect from us in CNC contract steel manufacturing. We carry out the CNC machining of your steel parts in special air-conditioned workshops. In this way, temperature-related deformations are reliably excluded and maximum precision is guaranteed. Do you need special steel components that are particularly small, large or thin-walled, for example? No problem: our experienced steel milling team is happy to take on any challenge and will find the right solution for your project.

We do not simply see ourselves as a service provider who can mill steel for you. Rather, we want to support you as a partner in your project. From the initial consultation to the final inspection, we therefore offer all services from a single source. We provide you with a dedicated contact person for all matters, ensuring that you receive exactly the components you need.

Overview of services CNC milled parts made of steel and other materials

| CNC Fräsen Stahl | Edelstahl, Manganstahl, Sicherheitsstahl, Werkzeugstahl, ballistischer Sicherheitsstahl, Duplex Stahl, Schmiedeteile aus rostfreien Stählen |

|---|---|

| CNC Fräsen Aluminium | Aluminiumlegierungen EN AW 5083, EN AW 7075, EN AW 6082, EN AW 6060, EN AW 6061, EN AW 2099, EN AW 2196, EN AW 2618, EN AW 5754, EN AW 5083, EN AW 6061, EN AW 6082 |

| CNC Fräsen weitere Materialien | Titan, Invar, CFK, GFK, verschiedene Kunststoffe |

| Werkstücklänge | bis 6000 mm |

| Gewicht | bis 20 t |

| Spezielle Verfahren | High Performance Cutting, High Speed Cutting |

| Zertifizierung | EN 9100:2018 |

HAVE STEEL MILLED

Which milled steel parts do you need at Taufkirchen?

Provide us with as much information as possible about your project for targeted CNC steel and metal processing. This will ensure that the result fully meets your expectations. Communication and close co-operation are a matter of course for us as part of our CNC service. The following information is particularly relevant for us if you have components milled from steel or stainless steel:

Intended use

If you have steel milled/CNC machined by us, we will customise the properties of the manufactured components precisely to your requirements. For example, should they be particularly resilient? Is a certain elasticity required? How should the parts react to temperature changes? These and many other properties can be realised with our modern CNC milling machines for steel processing. We would be happy to advise you personally on the optimum properties of your CNC steel components.

Design data

Based on your design and cutting data, we mill steel componentsthat precisely meet your specifications. From simple to highly complex shapes, (almost) anything is possible thanks to state-of-the-art manufacturing processes. If you have any questions or problems with your design, our specialists will be happy to help. If necessary, we can also work with you to optimise your design and adapt it even better to your requirements.

material

We mill your components from the material of your choice. Whether you want to have stainless steel milled, hardened steel machined or high-strength steel machined, you've come to the right place. The exact composition of the steel used has a significant impact on the properties of your finished components. Depending on the application, some steels are more and others less suitable. Are you unsure which material is best suited to your project? Just ask, we will be happy to advise you.

Deadline

Delays in delivery can affect downstream process steps and cause unnecessary costs. We therefore attach great importance to absolute adherence to deadlines. Modern machines and short decision-making processes also enable us to provide express CNC production of your components at short notice. Let us know as early as possible when you need your components so that we can plan and deliver accordingly.

Have steel CNC milled: Enquire about costs and delivery date now without obligation!

Production Manager

Compact Machines

Markus Meschenmoser

+49 7558 930-502

Send e-mail

VCard downloaden (.vcf)

Compact Machines

Markus Meschenmoser

+49 7558 930-502

Send e-mail

VCard downloaden (.vcf)

CNC milling steel: Online or at Laro NC-Technik?

Compared to CNC online milling providers, we not only offer economical and fast production, but also personalised advice and customised solutions that are tailored to your specific requirements. Our many years of experience and our commitment to the highest quality guarantee continuous process reliability. Laro NC-Technik Stahl Service works flexibly and can realise both small series and one-off productions economically and quickly. Our air-conditioned workshops guarantee absolute precision. Your project is too important to handle steel CNC milling online and anonymously. We make your project our project: personalised, reliable and on schedule. This makes us your ideal partner for CNC milled steel parts, stainless steel and other materials.

✔ Consultancy

We passionately contribute our wide-ranging repertoire of skills, experience and know-how to your project.

We passionately contribute our wide-ranging repertoire of skills, experience and know-how to your project.

✔ Process chain

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

Reliable manufacturing through virtualisation, air-conditioned manufacturing and integrated measurement in the machine.

✔ Quality management

We supplement strict certification requirements with regard to quality, reliability and traceability with our personal ambition and commitment.

We supplement strict certification requirements with regard to quality, reliability and traceability with our personal ambition and commitment.

✔ Express milling

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

Modern machines and short decision-making paths enable express CNC manufacturing for your urgent requirements.

CONTRACT MANUFACTURING STEEL 24/7

High Speed Cutting (HSC) milling of steel

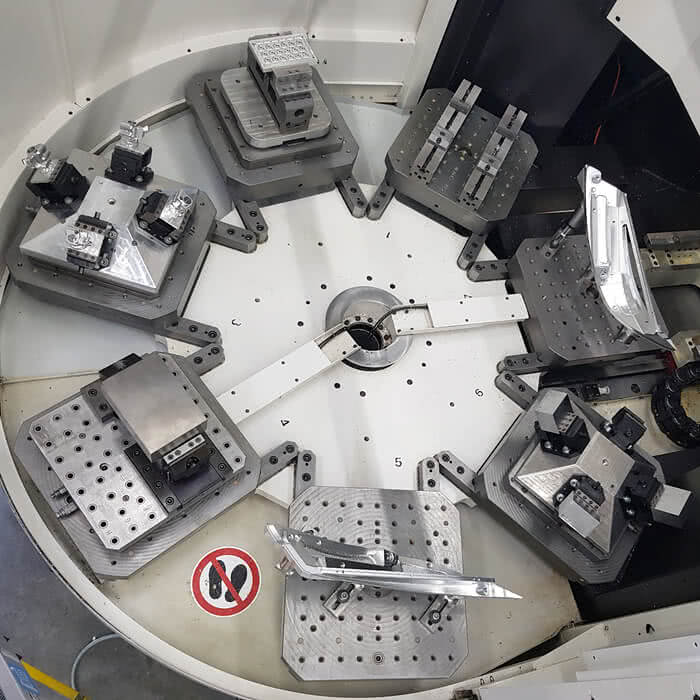

We have modern, high-performance machinery at our disposal for your milled steel parts. High-speed cutting (HSC milling) of steel means that even large milled parts can be produced particularly quickly. Whether hardened steel milling, high-strength steel milling or stainless steel milling: with our automated pallet changer, we are able to produce 24/7. We use automated production for small and medium series. The process does not need to be monitored and enables us to produce even faster - even overnight, at weekends and on public holidays. For express production or large quantities with consistently high quality.

From thin-walled, lightweight workpieces to heavy-duty machining: we manufacture highly complex components and guarantee end-to-end process reliability.

From thin-walled, lightweight workpieces to heavy-duty machining: we manufacture highly complex components and guarantee end-to-end process reliability.

| Verfahren | Typische Schwächen | Vorteil beim CNC-Fräsen |

|---|---|---|

CNC-Drehen | Einschränkungen in der Formgebung auf Regelgeometrie | Freiformflächen und komplexe Formgebung möglich |

Schweißen | Wärmeverzug/Gefügeveränderung an der Schweißnaht | Vergleichsweise geringe Wärmeentwicklung |

3D-Druck | Langsam häufig Nachbearbeitungen notwendig Metallgefüge oft ungleichmäßig | Schnelle Express-Fertigung i.d.R. keine Nachbearbeitung notwendig |

Wasserstrahlschneiden | Teilweise geringe Schnittgeschwindigkeit Rauheit der Oberfläche | Schnelle Express-Fertigung |

Laserschneiden | Wirkungsgrad variiert je nach Material Gefahr durch hohe Temperaturentwicklung | Zuverlässige, zügige Bearbeitung aller angegebenen Materialien Vergleichsweise geringe Wärmeentwicklung |

Metal Injection Molding | Hohe Kosten Eingeschränkte Wirtschaftlichkeit, insbesondere bei großen Teilen | Preiswert Wirtschaftlich sowohl bei Klein- als auch Großteilen |

Project process: customised steel milling using CNC machining

In addition to machining steel, we offer all upstream and downstream work steps from a single source. All the services required for this are either available in-house or are carried out by affiliated companies. As your system supplier and partner, we support you in all work steps relating to CNC steel milling. This is how a project works for us:

Consultancy

When you commission us to CNC mill steel components, we bring our wide-ranging expertise to your order right from the start. We advise you in detail and discuss any potential improvements to your design data with you. Specialists from various fields will work with you to find the optimum solution for your requirements. Our contact partners are available to answer any questions you may have throughout the entire process.

Feasibility study

We save time, material and order costs by offering to check the feasibility of your order in advance. The software simulates steel milling: CNC production in a virtual process. This allows us to visualise potential challenges in advance. If necessary, we then develop an optimised alternative to the original production concept.

Machining

We use your design data and our cutting data to mill steel components in sophisticated shapes in individual and series production. We machine and mill various types of steel, including stainless steel, precisely according to your requirements using automatic CNC milling machines. We mill simple notches and grooves in steel as well as producing sophisticated prototypes. Our modern and wide-ranging machine park has the right machine for every job.

Finish / quality control

On request, we can take care of the surface treatment of the finished components directly after production. Finally, our qualified employees carry out a final inspection. This ensures that all parts correspond exactly to the customer's requirements. Each component is automatically checked in the machine immediately after completion and then meticulously visually inspected by an experienced employee.

Round-the-clock production thanks to a high degree of automation

We use pallet changing systems to produce both series and individual parts fully automatically. We CNC mill stainless steel and other steels particularly efficiently and economically. This enables us to achieve maximum production quantities in the shortest possible time at favourable conditions. Alternatively, we can mill your individual item practically overnight as an express order for punctual delivery to Taufkirchen.

CNC milling steel: high-quality steel components are required in these areas

Steel is easy to machine, has high strength and good elongation at break properties. Combined with its versatility, low cost and almost unlimited recyclability, this makes steel a particularly useful material that plays a key role in many areas of industry. It is therefore no wonder that the production of steel exceeds that of all other metallic materials combined by a factor of more than ten.

CNC-milled steel components are used in these sectors, among others.

CNC-milled steel components are used in these sectors, among others.

Mechanical engineering

Steel is the standard material in the versatile field of mechanical engineering. To realise their designs, engineers rely on high-quality and precise components that have the exact dimensions and properties they require. We carry out steel and stainless steel machining/milling in close consultation with the customer. When we CNC mill steel or stainless steel components for you, the results meet your exact requirements and are precisely tailored to your project.

Automotive industry

CNC-milled steel components play an important role in the manufacture of motor vehicles. The right balance between weight and stability is often crucial here. Innovative ideas and approaches in the automotive industry require competent partners who can produce the required components reliably, on time and economically. Laro NC-Technik is the right partner for this. From the prototype to series production, we bring your designs precisely into shape.

Gear wheels

Even if you don't usually see them from the outside, gears are indispensable components in industry and mobility. They have to function absolutely reliably over a long period of time, often several years, and sometimes have to withstand high forces. It therefore makes sense to mill solid gears from steel blocks using CNC machines. We guarantee the required precision, quality and durability with qualified personnel, experience and state-of-the-art machines.

Construction industry

Durable steel components are essential for many construction machines. Whether teeth for excavator shovels or components for cranes: manufacturers of such vehicles must be able to rely on the fact that the components ordered are stable and have exactly the right dimensions. We always mill components made of steel and stainless steel exactly according to our customers' design data. Short communication channels enable us to take account of change requests, even at short notice.

Best contract manufacturing for steel CNC milling: Online or from Laro NC-Technik?

When it comes to CNC service, we are your full-service provider for companies in Taufkirchen with the all-round carefree package. Our range of services goes far beyond machining; we want to support you wherever you are. That is why the same contact person is always available to you directly and straightforwardly in all project phases.

From the idea to the finished component, we are the right contact for every project. You will be impressed by our customer-orientated company approach: fast response times, adherence to deadlines and openness to new ideas are just a few examples of what makes us stand out as a partner in machining. Our CNC milling services are affordable and reliable.

From the idea to the finished component, we are the right contact for every project. You will be impressed by our customer-orientated company approach: fast response times, adherence to deadlines and openness to new ideas are just a few examples of what makes us stand out as a partner in machining. Our CNC milling services are affordable and reliable.

Haben wir Ihr Interesse geweckt?

Vereinbaren Sie jetzt einen Termin für ein unverbindliches Beratungsgespräch!

Vertrieb

Tobias Kreft

+49 7558 930-514

E-Mail senden

VCard downloaden (.vcf)

Vereinbaren Sie jetzt einen Termin für ein unverbindliches Beratungsgespräch!

Vertrieb

Tobias Kreft

+49 7558 930-514

E-Mail senden

VCard downloaden (.vcf)

Taufkirchen, located in the picturesque heart of Bavaria, offers eine dynamische Umgebung, die durch eine vielfältige industriell geprägte Landschaft charakterisiert ist. Die Stadt ist bekannt für ihre hochmoderne Entwicklung im Maschinenbau und Fahrzeugbau, wo zahlreiche Unternehmen führende Technologien und Lösungen anbieten. Auch die Luft- und Raumfahrtindustrie findet durch verschiedene ansässige Firmen eine wichtige Heimat in Taufkirchen, die einen bedeutenden Beitrag zur Innovationskraft dieser Branche leisten.In diesem industriellen Kontext präsentiert sich die Laro NC-Technik GmbH als ein zuverlässiger und innovativer Partner in der CNC-Bearbeitung. Die Laro NC-Technik GmbH zeichnet sich durch ihr zertifiziertes Qualitätsmanagement nach höchsten Standards aus. Diese Zertifizierung ist ein Garant für die Qualität und Prozesssicherheit, die besonders wichtig für Unternehmen in den Hochtechnologie- und Präzisionssektoren sind, wie sie in Taufkirchen präsent sind.Die Flexibilität in der CNC-Fertigung bietet potenziellen Kunden entscheidende Vorteile: Ob es um die Herstellung von Werkstücken, Werkzeugen, Prototypen oder Cubing bis zu beachtlichen Längen geht – Laro NC-Technik kann eine breite Palette an Materialien bearbeiten. Dies spricht insbesondere Unternehmen aus dem Maschinenbau und der Luft- und Raumfahrt an, die oft maßgeschneiderte Lösungen benötigen, um ihren steigenden Anforderungen gerecht zu werden.Die geografische Lage von Taufkirchen ist ein weiterer strategischer Vorteil für die ansässigen Unternehmen. Die unmittelbare Nähe zu wichtigen Verkehrsanbindungen und der Ballungsraum München ermöglicht es, schnell und effizient mit Kunden und Partnern in Verbindung zu treten. Diese Erreichbarkeit ist besonders wertvoll für die synchronisierte Entwicklung und Fertigung von innovativen Lösungen, die in der schnelllebigen Industrie erforderlich sind.Die Laro NC-Technik GmbH bietet nicht nur Prozesssicherheit, sondern auch einen erstklassigen Full-Service, der von der Beratung über die CNC-Simulation bis hin zum finalen Frästeil reicht. Ein persönlicher Ansprechpartner begleitet die Projekte von Beginn bis Ende und sorgt dadurch für eine reibungslose Kommunikation sowie einen hohen Maß an Kundenzufriedenheit.Zusammengefasst bringt die Laro NC-Technik durch ihre vollständige Fertigung in Deutschland viele Vorteile mit sich. Kunden können sich auf hohe Qualität, schnelle Reaktionszeiten und die Gewissheit verlassen, dass ihre Produkte unter strengen deutschen Standards hergestellt werden. Ideal für die Innovationsstreben der Unternehmen in Taufkirchen, macht Laro NC-Technik den nächsten Schritt in der CNC Bearbeitung einfach und effektiv.

Have steel milled 85435 Erding | Have steel milled 85586 Poing | Have steel milled 85560 Ebersberg | Have steel milled 84130 Dingolfing | Have steel milled 85521 Ottobrunn | Have steel milled 82008 Unterhaching | Have steel milled 85757 Karlsfeld | Have steel milled 85221 Dachau | Have steel milled 93333 Neustadt an der Donau | Have steel milled 82140 Olching